×

- Hello

- Login or Register

- Quick Links

- Live Chat

- Track Order

- Parts Availability

- RMA

- Help Center

- Contact Us

- Shop for

- Subaru Parts

- Subaru Accessories

My Garage

My Account

Cart

Genuine Subaru Impreza Brake Master Cylinder

- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

26 Brake Master Cylinders found

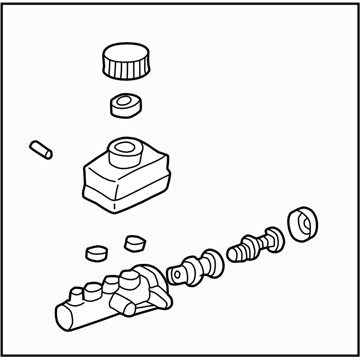

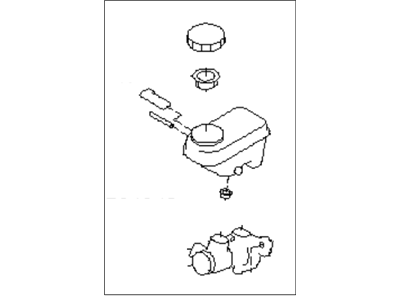

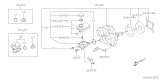

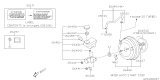

Subaru Impreza Master Cylinder Assembly

Part Number: 26401AC191$326.57 MSRP: $481.67You Save: $155.10 (33%)

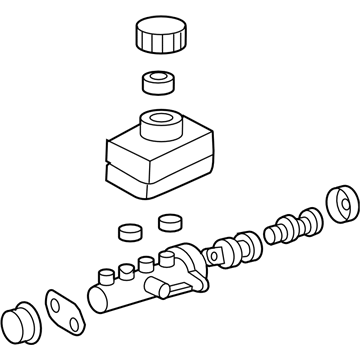

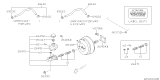

Subaru Impreza Master Cylinder Assembly (VDC)

Part Number: 26401AG030$165.63 MSRP: $242.15You Save: $76.52 (32%)Ships in 1-3 Business Days

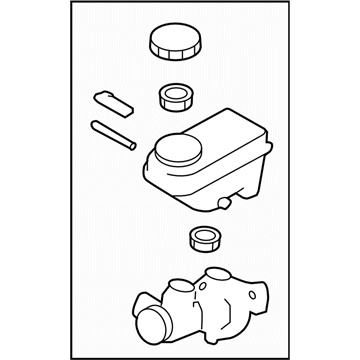

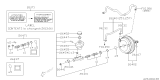

Subaru Impreza Master Cylinder Assembly

Part Number: 26401FA031$314.26 MSRP: $463.52You Save: $149.26 (33%)Ships in 1-3 Business Days

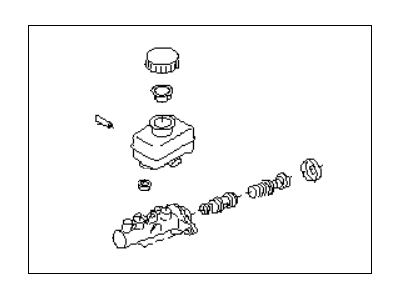

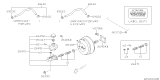

Subaru Impreza PB001351 Master Cylinder

Part Number: 26401FJ071$157.27 MSRP: $229.93You Save: $72.66 (32%)Ships in 1-3 Business Days

Subaru Impreza Master Cylinder Assembly

Part Number: 26401AC190$326.57 MSRP: $481.67You Save: $155.10 (33%)Ships in 1-3 Business Days

Subaru Impreza Master Cylinder Assembly

Part Number: 26401FJ070$157.27 MSRP: $229.93You Save: $72.66 (32%)Ships in 1-3 Business Days

Subaru Impreza Master Cylinder Assembly

Part Number: 26401FA100$672.16 MSRP: $991.38You Save: $319.22 (33%)Subaru Impreza Master Cylinder Kit

Part Number: 26449AL03A$153.98 MSRP: $225.12You Save: $71.14 (32%)Ships in 1-3 Business DaysSubaru Impreza Master Cylinder Assembly LH

Part Number: 26401FJ130$158.61 MSRP: $231.88You Save: $73.27 (32%)Ships in 1-3 Business DaysSubaru Impreza Master Cylinder Assembly

Part Number: 26401AC120$175.35 MSRP: $256.37You Save: $81.02 (32%)Ships in 1-3 Business DaysSubaru Impreza Master Cylinder Kit

Part Number: 26449AL02A$145.86 MSRP: $213.25You Save: $67.39 (32%)Ships in 1-3 Business DaysSubaru Impreza Master Cylinder Assembly

Part Number: 26401FJ060$150.91 MSRP: $220.63You Save: $69.72 (32%)Ships in 1-3 Business DaysSubaru Impreza MA CYL KIT

Part Number: 26449SL040$816.45 MSRP: $1204.20You Save: $387.75 (33%)Ships in 1-2 Business DaysSubaru Impreza PB001350 Master Cylinder

Part Number: 26401FJ061$150.91 MSRP: $220.63You Save: $69.72 (32%)Ships in 1-3 Business DaysSubaru Impreza Master Cylinder Assembly

Part Number: 26401AA240$125.33 MSRP: $181.63You Save: $56.30 (31%)Ships in 1-3 Business DaysSubaru Impreza Master Cylinder Assembly LH

Part Number: 26401FJ120$158.61 MSRP: $231.88You Save: $73.27 (32%)Ships in 1-3 Business DaysSubaru Impreza Master Cylinder Assembly

Part Number: 26401FA030$314.26 MSRP: $463.52You Save: $149.26 (33%)Ships in 1-3 Business DaysSubaru Impreza MA CYL KIT

Part Number: 26449FN012$816.53 MSRP: $1204.32You Save: $387.79 (33%)Ships in 1-2 Business Days

Subaru Impreza Master Cylinder Assembly (Abs)

Part Number: 26401AG010$146.41 MSRP: $214.05You Save: $67.64 (32%)

| Page 1 of 2 |Next >

1-20 of 26 Results

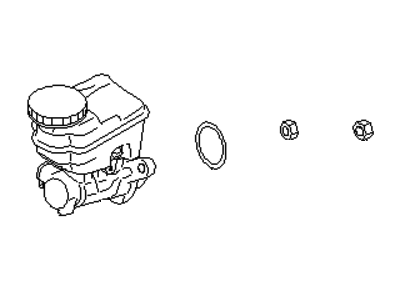

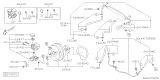

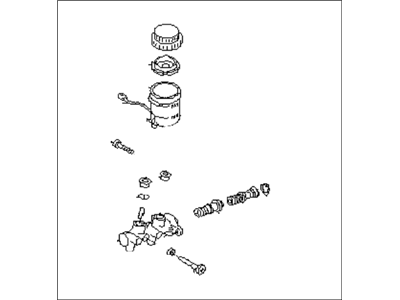

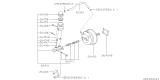

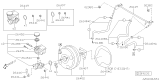

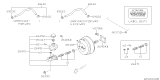

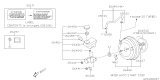

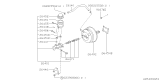

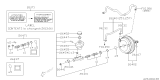

Subaru Impreza Brake Master Cylinder

The Subaru Impreza Brake Master Cylinder is a very important part that is behind the words; reliability and performance in Subaru products. This crucial component translates the pressure applied by the driver's foot into hydraulic pressure and managing the braking system via the distribution of the fluid to the slave cylinders that help in applying brakes. The Subaru Impreza Brake Master Cylinder as a rule has 2 circuits with two pistons and unlike many other automakers, the second circuit is only progressive, which means that in case one circuit is dead, the car automatically will remain with the second, and safety is improved. Available for probably all generations of the Subaru Impreza, ranging from the first introduced in 1992 up to the models, this Brake Master Cylinder is suitable for front-wheel drive as well as all-wheel drive versions of the car. First of all, there can be integrated or separate fluid reservoir in the Brake Master Cylinder, both have their strengths and weaknesses connected with the possibility of fluids storing and ease of maintenance. The structure of the Subaru Impreza Brake Master Cylinder is strong and usually produced using high quality materials which make it have a long life and fantastic performance in the markets. Periodic checkup and proper servicing of the Brake Master Cylinder are essential to avoid such problems like the leakage of the brake fluid to keep the vehicle's braking mechanism and safety in optimum condition. In totality, the Subaru Impreza Brake Master Cylinder captures the essence of the Subaru group by underlining the quality and inventiveness putting the Impreza compact car as a safe car in the market.

Our website stands as the go-to online destination for OEM Subaru Impreza Brake Master Cylinder. With complete lines of genuine Subaru Impreza Brake Master Cylinder available at unbeatable market prices, we ensure top quality, reliability, and durability. Each part comes backed by the manufacturer's warranty, reinforcing your trust in our offerings.

Subaru Impreza Brake Master Cylinder Parts Questions & Experts Answers

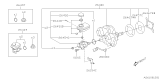

- Q: How to Replace a Brake Master Cylinder on a Subaru Impreza?A:Place some shop rags underneath the brake master cylinder to catch any spilled brake fluid, then remove the brake fluid from the reservoir. Unplug the electrical connector from the brake fluid level indicator and place some rags or newspapers under the brake line fittings. Using a flare-nut wrench, unscrew the brake line tube nuts and allow any residual fluid to drain onto the rags. Remove the brake master cylinder-to-power brake booster mounting nuts and remove the brake master cylinder from the engine compartment. If a new brake master cylinder is being installed, the power brake booster pushrod length must be checked and adjusted. Bench bleed the new brake master cylinder before installing it, attach a pair of brake master cylinder bleeder tubes to the outlet ports of the brake master cylinder, fill the reservoir with brake fluid, slowly push the pistons into the brake master cylinder, remove the bleed tubes, one at a time and install plugs in the open ports to prevent fluid leakage and air from entering, replace the O-ring seal on the brake master cylinder, thread the brake line fittings into the brake master cylinder, fill the brake master cylinder reservoir with fluid, then bleed the brake master cylinder and the brake system, have an assistant depress the brake pedal and hold the pedal to the floor, loosen the fitting just enough to allow air and fluid to escape then tighten it lightly, repeat this procedure on both fittings until the fluid is clear of air bubbles and then tighten the fittings securely, rinse the area under the brake master cylinder with clean water, fully tighten the mounting nuts, then the brake line fittings, tighten the brake master cylinder mounting nuts, and test the operation of the brake system carefully before placing the vehicle into normal service.

Related Subaru Impreza Parts

Browse by Year

2025 Brake Master Cylinder 2024 Brake Master Cylinder 2023 Brake Master Cylinder 2022 Brake Master Cylinder 2021 Brake Master Cylinder 2020 Brake Master Cylinder 2019 Brake Master Cylinder 2018 Brake Master Cylinder 2017 Brake Master Cylinder 2016 Brake Master Cylinder 2015 Brake Master Cylinder 2014 Brake Master Cylinder 2013 Brake Master Cylinder 2012 Brake Master Cylinder 2011 Brake Master Cylinder 2010 Brake Master Cylinder 2009 Brake Master Cylinder 2008 Brake Master Cylinder 2007 Brake Master Cylinder 2006 Brake Master Cylinder 2005 Brake Master Cylinder 2004 Brake Master Cylinder 2003 Brake Master Cylinder 2002 Brake Master Cylinder 2001 Brake Master Cylinder 2000 Brake Master Cylinder 1999 Brake Master Cylinder 1998 Brake Master Cylinder 1997 Brake Master Cylinder 1996 Brake Master Cylinder 1995 Brake Master Cylinder 1994 Brake Master Cylinder 1993 Brake Master Cylinder