×

- Hello

- Login or Register

- Quick Links

- Live Chat

- Track Order

- Parts Availability

- RMA

- Help Center

- Contact Us

- Shop for

- Subaru Parts

- Subaru Accessories

My Garage

My Account

Cart

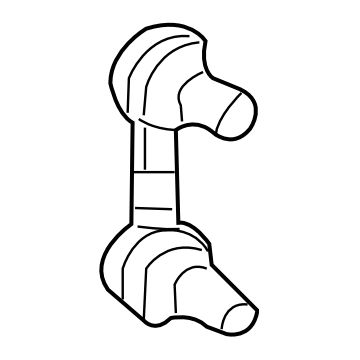

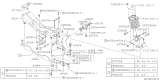

Genuine Subaru Forester Sway Bar Link

Stabilizer Sway Bar Link- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

14 Sway Bar Links found

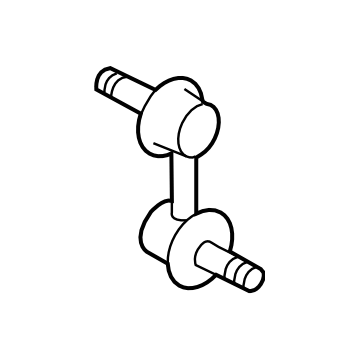

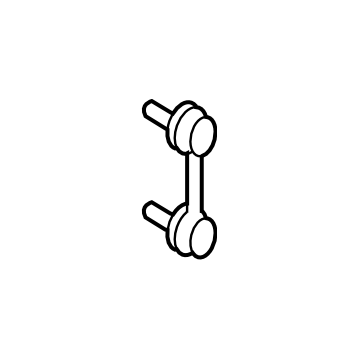

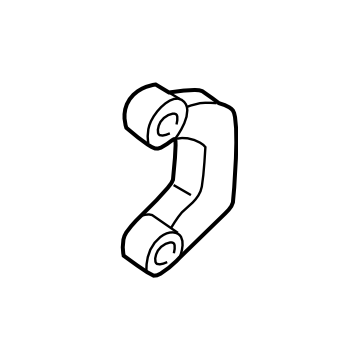

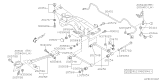

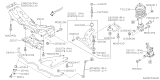

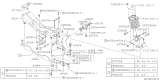

Subaru Forester Link Assembly Front STABILIZER

Part Number: 20420XA000$44.09 MSRP: $63.90You Save: $19.81 (31%)Ships in 1-3 Business Days

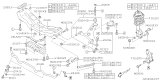

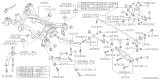

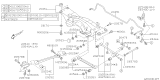

Subaru Forester Stabilizer Link

Part Number: 20470SA001$38.15 MSRP: $55.28You Save: $17.13 (31%)Ships in 1-3 Business Days

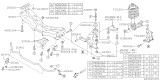

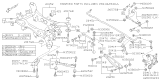

Subaru Forester Link Assembly STABILIZER Front

Part Number: 20420FL020$30.23 MSRP: $43.82You Save: $13.59 (32%)Ships in 1-2 Business Days

Subaru Forester Link Assembly STABILIZER Front

Part Number: 20420FL030$30.23 MSRP: $43.82You Save: $13.59 (32%)Ships in 1-3 Business Days

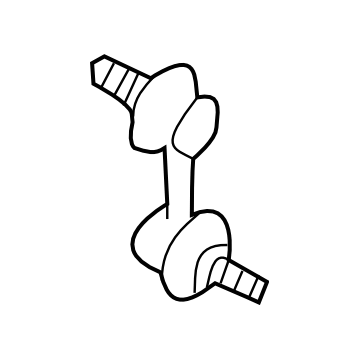

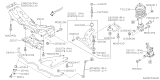

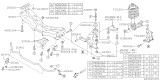

Subaru Forester STABILIZER Lk Rear

Part Number: 20470AJ010$43.65 MSRP: $63.27You Save: $19.62 (32%)Ships in 1-2 Business Days

Subaru Forester Link Assembly STABILIZER Rear Rear

Part Number: 20470FL000$44.74 MSRP: $64.83You Save: $20.09 (31%)Ships in 1-3 Business Days

Subaru Forester Link Assembly Front STABILIZER

Part Number: 20470SA000$38.15 MSRP: $55.28You Save: $17.13 (31%)Ships in 1-3 Business Days

Subaru Forester STABILIZER Link Assembly Front

Part Number: 20420AA004$43.46 MSRP: $62.98You Save: $19.52 (31%)Ships in 1-2 Business Days

Subaru Forester Link Assembly STABILIZER Rear

Part Number: 20470SA011$29.49 MSRP: $42.73You Save: $13.24 (31%)Ships in 1-3 Business Days

Subaru Forester STABILIZER Link Assembly Rear

Part Number: 20481AA001$76.36 MSRP: $110.67You Save: $34.31 (31%)Ships in 1 Business Day

Subaru Forester Link Assembly STABILIZER Rear

Part Number: 20470SC000$43.65 MSRP: $63.27You Save: $19.62 (32%)Ships in 1-3 Business Days

Subaru Forester STABILIZER Link Assembly Front

Part Number: 20420AA003$43.46 MSRP: $62.98You Save: $19.52 (31%)Ships in 1-2 Business DaysSubaru Forester Link Assembly STABILIZER Rear L

Part Number: 20470FL010$44.74 MSRP: $64.83You Save: $20.09 (31%)Ships in 1-3 Business DaysSubaru Forester Link Assembly STABILIZER Rear

Part Number: 20470SA010$29.49 MSRP: $42.73You Save: $13.24 (31%)Ships in 1-3 Business Days

Subaru Forester Sway Bar Link

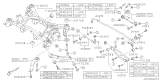

Our website stands as the go-to online destination for OEM Subaru Forester Sway Bar Link. With complete lines of genuine Subaru Forester Sway Bar Link available at unbeatable market prices, we ensure top quality, reliability, and durability. Each part comes backed by the manufacturer's warranty, reinforcing your trust in our offerings.

Subaru Forester Sway Bar Link Parts Questions & Experts Answers

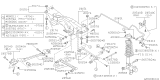

- Q: How to Install a Sway Bar Kit and Sway Bar Link on a Subaru Forester?A:New 'self-locking' mounting nuts should be used when fitting the sway bar links as recommended by the manufacturer. First, free the wheel lug nuts then block the rear wheels, lift the front part of the motor vehicle and place it securely on jack stands then remove the front wheels. Subsequently, if there is one, remove the nuts of the links connecting the sway bar kit to the Control Arms, and then remove the fasteners of the clips of the sway bar bushing. For late model link designs, loosen the nut with an Allen head screw that is placed at the end of the link's ballstud. Next take off the sway bar bushing clamps and the sway bar kit for additional information of the repair procedure. Go further to unbolt the bushings from the sway bar kit and perform crack, deterioration or general ageing check on the bushing and for the sway bar kit, check the curved parts likewise the deformation and replace parts where necessary. There is a tradition of installing systems in reverse order to the removal process with specific effort being applied to the fasteners to bring them to the correct torque. Last, fix the wheels and lug nuts, drop the car, and tighten the lug nuts to the recommended pound-force.

Related Subaru Forester Parts

Browse by Year

2025 Sway Bar Link 2024 Sway Bar Link 2023 Sway Bar Link 2022 Sway Bar Link 2021 Sway Bar Link 2020 Sway Bar Link 2019 Sway Bar Link 2018 Sway Bar Link 2017 Sway Bar Link 2016 Sway Bar Link 2015 Sway Bar Link 2014 Sway Bar Link 2013 Sway Bar Link 2012 Sway Bar Link 2011 Sway Bar Link 2010 Sway Bar Link 2009 Sway Bar Link 2008 Sway Bar Link 2007 Sway Bar Link 2006 Sway Bar Link 2005 Sway Bar Link 2004 Sway Bar Link 2003 Sway Bar Link 2002 Sway Bar Link 2001 Sway Bar Link 2000 Sway Bar Link 1999 Sway Bar Link 1998 Sway Bar Link