×

- Hello

- Login or Register

- Quick Links

- Live Chat

- Track Order

- Parts Availability

- RMA

- Help Center

- Contact Us

- Shop for

- Subaru Parts

- Subaru Accessories

My Garage

My Account

Cart

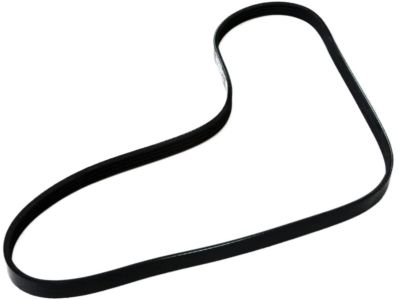

Genuine Subaru Impreza Drive Belt

Serpentine Belt- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

12 Drive Belts found

Subaru Impreza Belt Set

Part Number: 11718AA082$57.24 MSRP: $82.95You Save: $25.71 (31%)Ships in 1-3 Business Days

Subaru Impreza V Belt 21X4X1960

Part Number: 809221210$31.91 MSRP: $46.25You Save: $14.34 (32%)Ships in 1-3 Business Days

Subaru Impreza A/C Belt

Part Number: 73323AC000$15.26 MSRP: $22.12You Save: $6.86 (32%)Ships in 1-3 Business Days

Subaru Impreza V Belt 21 X 4 X 2155

Part Number: 809221170$37.34 MSRP: $54.12You Save: $16.78 (32%)Ships in 1-3 Business Days

Subaru Impreza V Belt

Part Number: 809218430$18.14 MSRP: $26.28You Save: $8.14 (31%)Ships in 1-3 Business Days

Subaru Impreza V Belt

Part Number: 23780AA08A$28.46 MSRP: $41.25You Save: $12.79 (32%)Ships in 1 Business Day

Subaru Impreza Belt Compressor

Part Number: 73323AC011$15.26 MSRP: $22.12You Save: $6.86 (32%)Ships in 1-3 Business Days

Subaru Impreza A/C Belt

Part Number: 73323AC010$15.26 MSRP: $22.12You Save: $6.86 (32%)Ships in 1-3 Business Days

Subaru Impreza A/C Belt

Part Number: 73013AA000$12.00 MSRP: $16.95You Save: $4.95 (30%)Ships in 1-3 Business Days

Subaru Impreza Belt Set

Part Number: 11718AA081$57.24 MSRP: $82.95You Save: $25.71 (31%)Ships in 1-3 Business DaysSubaru Impreza V Belt

Part Number: 23780AA230$36.58 MSRP: $53.02You Save: $16.44 (32%)Ships in 1-3 Business DaysSubaru Impreza A/C Belt

Part Number: 73323FA000$12.00 MSRP: $16.95You Save: $4.95 (30%)Ships in 1-3 Business Days

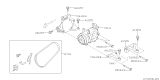

Subaru Impreza Drive Belt

Our website stands as the go-to online destination for OEM Subaru Impreza Drive Belt. With complete lines of genuine Subaru Impreza Drive Belt available at unbeatable market prices, we ensure top quality, reliability, and durability. Each part comes backed by the manufacturer's warranty, reinforcing your trust in our offerings.

Subaru Impreza Drive Belt Parts Questions & Experts Answers

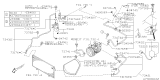

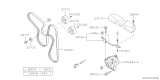

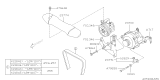

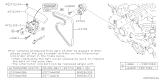

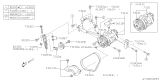

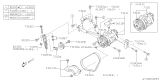

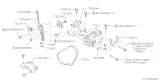

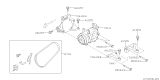

- Q: How to inspect, adjust, and replace drive belts and tensioners on Subaru Impreza?A:Engine belts that deteriorate over time are positioned at the front of the engine and play a critical role in avoiding costly damage. The number of belts differs from one vehicle to another but usually drives alternator, power steering pump and air conditioning compressor. To check them, open the hood with the motor off and look for cracks, separation, fraying or glazing while noticing their vein; they should appear nice and even. The tension of a belt is determined through pressing it down in between two pulleys where it should drop about 1/4 inch. Setting up the tension requires loosening a lock bolt on an adjustment assembly as well as rotating a slide bolt then rechecking it before tightening both bolts again. In order to change one's old belt however, it has to be replaced by new one which must be marked after removing the former using adjusting method when marking belts and pulleys is done properly. While changing out an older AC compressor belt built 2008 or later on use a pry bar to relieve pressure. Replacing drive belts for earlier models built in 2007 or less comprise removal of belt cover; drive belt itself; tensioner bracket; tensioner bolt; put back everything together starting from reverse order.

Related Subaru Impreza Parts

Browse by Year

2025 Drive Belt 2024 Drive Belt 2023 Drive Belt 2022 Drive Belt 2021 Drive Belt 2020 Drive Belt 2019 Drive Belt 2018 Drive Belt 2017 Drive Belt 2016 Drive Belt 2015 Drive Belt 2014 Drive Belt 2013 Drive Belt 2012 Drive Belt 2011 Drive Belt 2010 Drive Belt 2009 Drive Belt 2008 Drive Belt 2007 Drive Belt 2006 Drive Belt 2005 Drive Belt 2004 Drive Belt 2003 Drive Belt 2002 Drive Belt 2001 Drive Belt 2000 Drive Belt 1999 Drive Belt 1998 Drive Belt 1997 Drive Belt 1996 Drive Belt 1995 Drive Belt 1994 Drive Belt 1993 Drive Belt