×

- Hello

- Login or Register

- Quick Links

- Live Chat

- Track Order

- Parts Availability

- RMA

- Help Center

- Contact Us

- Shop for

- Subaru Parts

- Subaru Accessories

My Garage

My Account

Cart

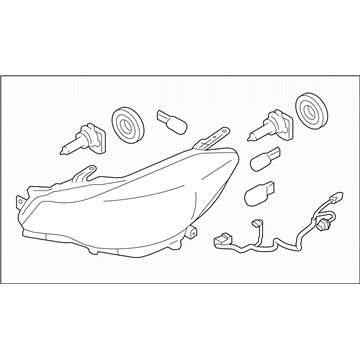

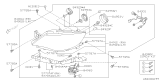

Genuine Subaru Impreza Headlight

Headlamp- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

94 Headlights found

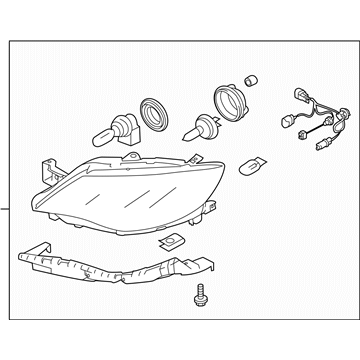

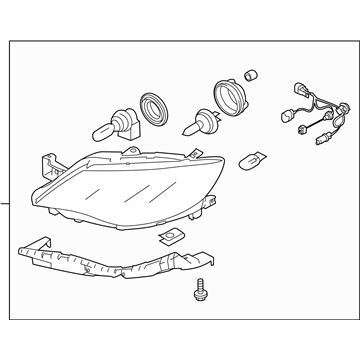

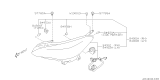

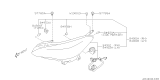

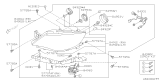

Subaru Impreza Headlamp Assembly Driver Side

Part Number: 84001FG251$340.04 MSRP: $501.53You Save: $161.49 (33%)Ships in 1-2 Business Days

Subaru Impreza Headlamp Assembly Driver Side

Part Number: 84001FJ091$319.29 MSRP: $470.93You Save: $151.64 (33%)Ships in 1-3 Business Days

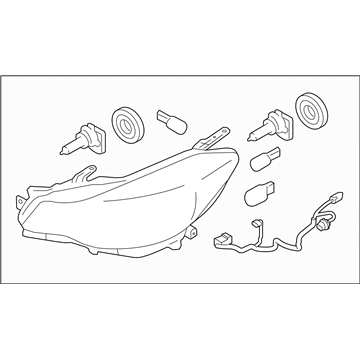

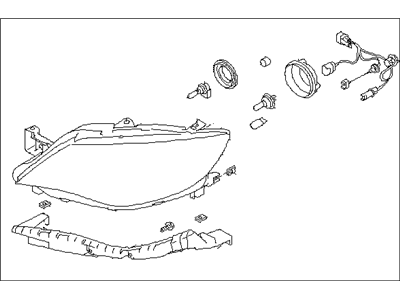

Subaru Impreza Headlamp Assembly Passenger Side

Part Number: 84002FL061$828.09 MSRP: $1221.37You Save: $393.28 (33%)Ships in 1-3 Business Days

Subaru Impreza Headlamp Assembly Driver Side

Part Number: 84001FL01A$218.85 MSRP: $319.95You Save: $101.10 (32%)Ships in 1-3 Business Days

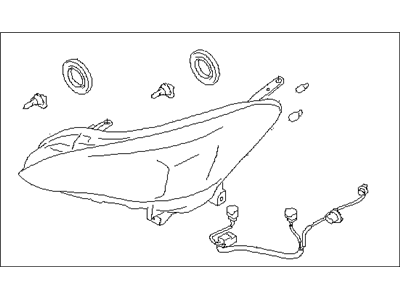

Subaru Impreza Headlamp Assembly Passenger Side

Part Number: 84001FG241$340.04 MSRP: $501.53You Save: $161.49 (33%)Ships in 1-3 Business Days

Subaru Impreza Headlamp Assembly Passenger Side

Part Number: 84001FL00A$218.85 MSRP: $319.95You Save: $101.10 (32%)Ships in 1-3 Business Days

Subaru Impreza Headlamp Assembly Driver Side

Part Number: 84001FJ330$300.81 MSRP: $443.67You Save: $142.86 (33%)Ships in 1-3 Business Days

Subaru Impreza Headlamp Assembly Passenger Side

Part Number: 84001FJ320$300.81 MSRP: $443.67You Save: $142.86 (33%)Ships in 1-3 Business Days

Subaru Impreza Headlamp Assembly Passenger Side

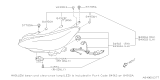

Part Number: 84001FG240$340.04 MSRP: $501.53You Save: $161.49 (33%)Ships in 1-2 Business DaysSubaru Impreza Lamp Assembly Head A

Part Number: 84001FL01B$218.85 MSRP: $319.95You Save: $101.10 (32%)Ships in 1-3 Business DaysSubaru Impreza Lamp Head A. (Right).

Part Number: 84001FL00B$218.85 MSRP: $319.95You Save: $101.10 (32%)Ships in 1-2 Business DaysSubaru Impreza Head Lamp Assembly

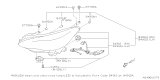

Part Number: 84002FL612$776.48 MSRP: $1145.25You Save: $368.77 (33%)Ships in 1-3 Business DaysSubaru Impreza LAMP ASSY HEAD ULL

Part Number: 84002FN01A$770.64 MSRP: $1136.63You Save: $365.99 (33%)Subaru Impreza Head Lamp Assembly

Part Number: 84002FL602$776.48 MSRP: $1145.25You Save: $368.77 (33%)Ships in 1-3 Business DaysSubaru Impreza Headlamp Assembly Passenger Side

Part Number: 84001FJ081$319.29 MSRP: $470.93You Save: $151.64 (33%)Ships in 1-3 Business DaysSubaru Impreza LAMP ASSY HEAD ULR

Part Number: 84002FN00A$770.64 MSRP: $1136.63You Save: $365.99 (33%)Subaru Impreza Head Lamp Assembly

Part Number: 84001FN000$802.05 MSRP: $1182.97You Save: $380.92 (33%)Ships in 1-2 Business DaysSubaru Impreza Headlamp Assembly Driver Side

Part Number: 84002FL071$828.09 MSRP: $1221.37You Save: $393.28 (33%)Ships in 1-3 Business DaysSubaru Impreza Head Lamp Assembly

Part Number: 84001FN010$802.05 MSRP: $1182.97You Save: $380.92 (33%)Ships in 1-2 Business DaysSubaru Impreza Headlamp Assembly Passenger Side

Part Number: 84001FJ080$319.29 MSRP: $470.93You Save: $151.64 (33%)Ships in 1-3 Business Days

| Page 1 of 5 |Next >

1-20 of 94 Results

Subaru Impreza Headlight

Our website stands as the go-to online destination for OEM Subaru Impreza Headlight. With complete lines of genuine Subaru Impreza Headlight available at unbeatable market prices, we ensure top quality, reliability, and durability. Each part comes backed by the manufacturer's warranty, reinforcing your trust in our offerings.

Subaru Impreza Headlight Parts Questions & Experts Answers

- Q: What is the importance of correct aiming of headlights on Subaru Impreza?A:For accident avoidance and to prevent the dazzling of oncoming drivers, proper aiming of headlights is necessary. This implies that the aim of the headlights should be checked every twelve months, when new headlamps are installed or front end bodywork conducted. Here is how you can make temporary adjustments for your headlights: Each headlight has a single adjusting screw that adjusts up-and-down movement. The easiest method involves using a level floor and a blank wall 25 feet away from the vehicle. In reference to both headlights' centerlines and the vehicle centerline, set masking tape vertically on the wall. Also, there should be a horizontal tape line in reference to all of them. It is easier to position the tape on the wall with the vehicle parked a few inches away. Ensure that gas tank is half full; there are no unusually heavy loads; and vehicle is level . For low beam adjustment start by positioning high intensity zone two inches below horizontal line and two inches to right of head light vertical line. Then use adjusting screw to raise or lower beam Low beams will have their high intensity zones horizontally aligned just below this horizontal line as well when high beams are turned on If compromise becomes necessary, give priority to correct aim of low beams because they are used most and affect driver safety more than anything else It would be best if you could have them adjusted at the dealer's service department or at an automotive service station without delay.

Related Subaru Impreza Parts

Browse by Year

2025 Headlight 2024 Headlight 2023 Headlight 2022 Headlight 2021 Headlight 2020 Headlight 2019 Headlight 2018 Headlight 2017 Headlight 2016 Headlight 2015 Headlight 2014 Headlight 2013 Headlight 2012 Headlight 2011 Headlight 2010 Headlight 2009 Headlight 2008 Headlight 2007 Headlight 2006 Headlight 2005 Headlight 2004 Headlight 2003 Headlight 2002 Headlight 2001 Headlight 2000 Headlight 1999 Headlight 1998 Headlight 1997 Headlight 1996 Headlight 1995 Headlight 1994 Headlight 1993 Headlight