×

- Hello

- Login or Register

- Quick Links

- Live Chat

- Track Order

- Parts Availability

- RMA

- Help Center

- Contact Us

- Shop for

- Subaru Parts

- Subaru Accessories

My Garage

My Account

Cart

Genuine Subaru Legacy Headlight

Headlamp- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

87 Headlights found

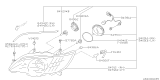

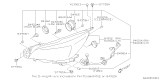

Subaru Legacy Headlamp Halogen LH Headlamp

Part Number: 84001AL11A$320.20 MSRP: $472.27You Save: $152.07 (33%)Ships in 1-2 Business Days

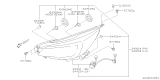

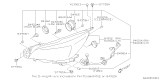

Subaru Legacy Driver Side Headlamp Assembly With Black

Part Number: 84001AL03A$254.93 MSRP: $372.70You Save: $117.77 (32%)Ships in 1-3 Business DaysSubaru Legacy Headlamp Assembly Passenger Side

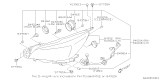

Part Number: 84002AN12A$467.45 MSRP: $689.45You Save: $222.00 (33%)Ships in 1-2 Business Days

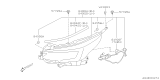

Subaru Legacy Headlamp Assembly Passenger Side

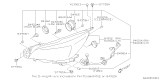

Part Number: 84001AL02A$254.93 MSRP: $372.70You Save: $117.77 (32%)Ships in 1-3 Business Days

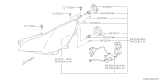

Subaru Legacy Headlamp Assembly Passenger Side

Part Number: 84002AL00A$565.43 MSRP: $833.97You Save: $268.54 (33%)

Subaru Legacy Headlamp Assembly Driver Side

Part Number: 84002AL01A$565.43 MSRP: $833.97You Save: $268.54 (33%)

Subaru Legacy Headlamp Assembly Passenger Side

Part Number: 84002AN10A$387.40 MSRP: $571.38You Save: $183.98 (33%)Ships in 1-3 Business Days

Subaru Legacy Headlamp Assembly Passenger Side

Part Number: 84001AJ22A$369.76 MSRP: $545.37You Save: $175.61 (33%)Ships in 1-3 Business DaysSubaru Legacy Headlamp Assembly Driver Side

Part Number: 84002AN13A$467.45 MSRP: $689.45You Save: $222.00 (33%)Ships in 1-2 Business DaysSubaru Legacy Headlamp Assembly Passenger Side

Part Number: 84001AL10A$320.20 MSRP: $472.27You Save: $152.07 (33%)Ships in 1-2 Business DaysSubaru Legacy LAMP ASSY HEAD ULL

Part Number: 84002AN51A$583.70 MSRP: $860.92You Save: $277.22 (33%)Ships in 1-3 Business DaysSubaru Legacy Headlamp Assembly Driver Side

Part Number: 84002AN11A$387.40 MSRP: $571.38You Save: $183.98 (33%)Ships in 1-2 Business DaysSubaru Legacy LAMP ASSY HEAD ULR

Part Number: 84002AN50A$583.70 MSRP: $860.92You Save: $277.22 (33%)Ships in 1-3 Business DaysSubaru Legacy Headlamp Assembly Passenger Side

Part Number: 84001AL00A$261.01 MSRP: $381.60You Save: $120.59 (32%)Ships in 1-3 Business DaysSubaru Legacy Headlamp Assembly Passenger Side

Part Number: 84002AL10A$589.16 MSRP: $868.97You Save: $279.81 (33%)Ships in 1 Business DaySubaru Legacy Headlamp Driver Side

Part Number: 84002AN15A$643.79 MSRP: $949.55You Save: $305.76 (33%)Ships in 1-3 Business DaysSubaru Legacy Headlamp Assembly Passenger Side

Part Number: 84002AN14A$643.79 MSRP: $949.55You Save: $305.76 (33%)Ships in 1-2 Business DaysSubaru Legacy Headlamp Assembly Passenger Side

Part Number: 84002AL10B$589.16 MSRP: $868.97You Save: $279.81 (33%)Ships in 1-2 Business DaysSubaru Legacy Headlamp Assembly Driver Side

Part Number: 84001AL01A$261.01 MSRP: $381.60You Save: $120.59 (32%)Ships in 1-3 Business DaysSubaru Legacy Headlamp Assembly Driver Side

Part Number: 84001AG53B$348.80 MSRP: $514.45You Save: $165.65 (33%)Ships in 1-3 Business Days

| Page 1 of 5 |Next >

1-20 of 87 Results

Subaru Legacy Headlight

Our website stands as the go-to online destination for OEM Subaru Legacy Headlight. With complete lines of genuine Subaru Legacy Headlight available at unbeatable market prices, we ensure top quality, reliability, and durability. Each part comes backed by the manufacturer's warranty, reinforcing your trust in our offerings.

Subaru Legacy Headlight Parts Questions & Experts Answers

- Q: How should headlights be aimed correctly to ensure driver safety on Subaru Legacy?A:The headlights need always to be aimed properly so that motorists on the road ahead are not blinded and visibility is enhanced on the roads. In light of the above, it is recommended that the aim should be checked at least once in a year or each time a new headlight is fitted or front-end bodywork is carried out. The following procedure offers a temporary fix until the client can find a pro who can realign the car: The vertical adjustment of each light is controlled by respectively providing one adjusting screw to each light. A basic technique includes using blank wall, which is at a distance of half the length of the vehicle from it and a level floor. The vertical masking tape should be put on the wall while it is parallel to the vehicle's center line and the center point of each headlight; a horizontal line of the masking tapes should also be drawn for convenience. Required position with respect to car should be said to be leaning and the fuel indicator should be near half full and there should be no heavy items in the car. Low beam adjustment increasing the high-intensity zone of two inches below the horizontal line and two inches to the right of the headlight vertical line is done by turning the adjusting screw. Indeed, if the high beams are activated, the high-intensity zone should be positioned slightly below the horizontal line of the figure. Sometimes, it may not be possible to have an alignment that meets standards for both the high and the low beams Therefore it is safe to opt for the low beams. Take the car for an alignment as soon as possible especially the headlights.

Related Subaru Legacy Parts

Browse by Year

2025 Headlight 2024 Headlight 2023 Headlight 2022 Headlight 2021 Headlight 2020 Headlight 2019 Headlight 2018 Headlight 2017 Headlight 2016 Headlight 2015 Headlight 2014 Headlight 2013 Headlight 2012 Headlight 2011 Headlight 2010 Headlight 2009 Headlight 2008 Headlight 2007 Headlight 2006 Headlight 2005 Headlight 2004 Headlight 2003 Headlight 2002 Headlight 2001 Headlight 2000 Headlight 1999 Headlight 1998 Headlight 1997 Headlight 1996 Headlight 1995 Headlight 1994 Headlight 1993 Headlight 1992 Headlight 1991 Headlight 1990 Headlight