×

- Hello

- Login or Register

- Quick Links

- Live Chat

- Track Order

- Parts Availability

- RMA

- Help Center

- Contact Us

- Shop for

- Subaru Parts

- Subaru Accessories

My Garage

My Account

Cart

Genuine Subaru Forester Brake Line

Brake Hose- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

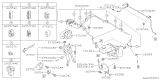

44 Brake Lines found

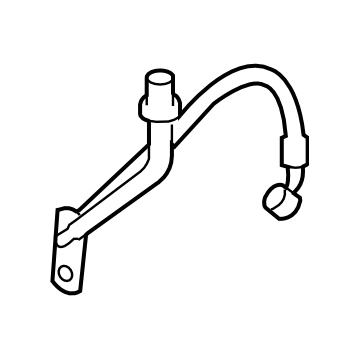

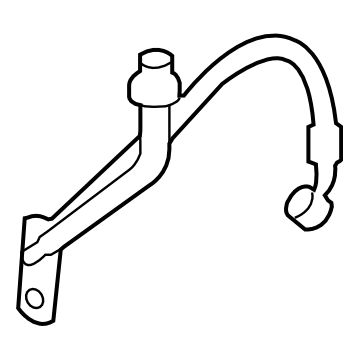

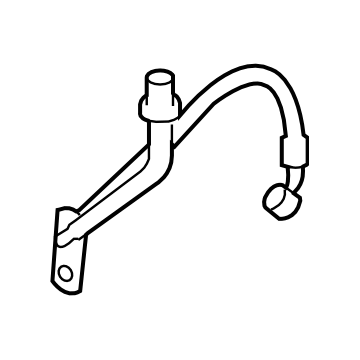

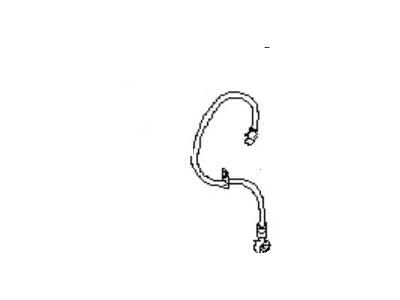

Subaru Forester Brake Hose Front RH

Part Number: 26540SC002$38.33 MSRP: $55.55You Save: $17.22 (31%)Ships in 1-2 Business DaysSubaru Forester BRAKE HOSE R LH

Part Number: 26541FN051$40.25 MSRP: $58.33You Save: $18.08 (31%)Ships in 1-2 Business DaysSubaru Forester BRAKE HOSE F LH

Part Number: 26540AN051$35.18 MSRP: $50.98You Save: $15.80 (31%)Ships in 1-2 Business DaysSubaru Forester Brake Hose Front LH

Part Number: 26540SC012$38.33 MSRP: $55.55You Save: $17.22 (31%)Ships in 1-2 Business DaysSubaru Forester BRAKE HOSE R RH

Part Number: 26541FN041$40.25 MSRP: $58.33You Save: $18.08 (31%)Ships in 1-2 Business DaysSubaru Forester BRAKE HOSE F RH

Part Number: 26540AN060$16.69 MSRP: $24.18You Save: $7.49 (31%)Ships in 1-2 Business DaysSubaru Forester Brake Hose Rear Left

Part Number: 26541FJ051$38.33 MSRP: $55.55You Save: $17.22 (31%)Ships in 1-3 Business DaysSubaru Forester Brake Hose Rear Right

Part Number: 26541FJ041$38.33 MSRP: $55.55You Save: $17.22 (31%)Ships in 1-3 Business DaysSubaru Forester Brake Hose Rear RH

Part Number: 26541SG001$39.28 MSRP: $56.93You Save: $17.65 (31%)Ships in 1-3 Business DaysSubaru Forester Brake Hose Rear Left Hand

Part Number: 26541SG011$39.28 MSRP: $56.93You Save: $17.65 (31%)Ships in 1-3 Business DaysSubaru Forester BRAKE HOSE R LH

Part Number: 26541FN110$44.00 MSRP: $63.77You Save: $19.77 (31%)Ships in 1-2 Business DaysSubaru Forester BRAKE HOSE F LH

Part Number: 26540AN070$16.69 MSRP: $24.18You Save: $7.49 (31%)Ships in 1-2 Business DaysSubaru Forester Brake Hose Rear RH

Part Number: 26591SC001$42.16 MSRP: $61.10You Save: $18.94 (31%)Ships in 1-3 Business DaysSubaru Forester BRAKE HOSE F RH

Part Number: 26540AN041$35.18 MSRP: $50.98You Save: $15.80 (31%)Ships in 1-2 Business DaysSubaru Forester Brake Hose Front RH

Part Number: 26540AE010$38.64 MSRP: $56.00You Save: $17.36 (31%)Ships in 1-3 Business Days

| Page 1 of 3 |Next >

1-20 of 44 Results

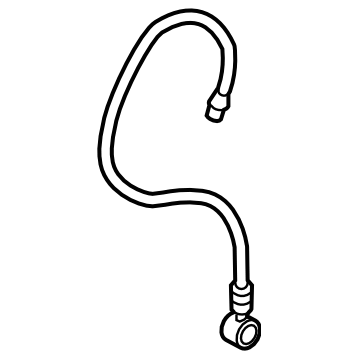

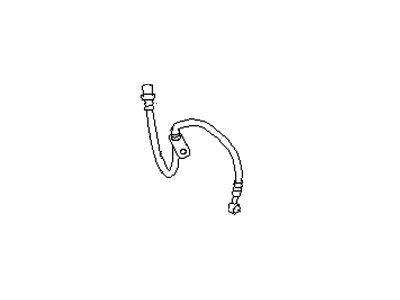

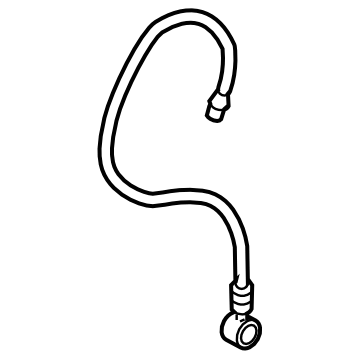

Subaru Forester Brake Line

The Brake Line in Subaru Forester cars plays an integral role in the distribution of brake fluids from the master cylinder to the brake caliper so that the operation of the hydraulic braking system in these vehicles is possible. This component can also comprise of metal or flexible hose, both functioning normally to transmit the hydraulic pressure for effective braking (elements). Over the years, there have been different types of Subaru Brake Line, with the ones made of metals being vulnerable to corrosion, especially during the winter seasons, causing leakage of the hydraulic pressure. Also, Subaru Forester Brake Line can be physically damaged (cracks and abrasion) as well as interior damaged (incorrect installation and contamination). The altered vehicle Subaru Forester Brake Line system ultimately compromises safety. Maintenance of braking performance and safety in these vehicles is through regular inspection for signs of damage. Hundreds of drivers lose their lives because of unusual brake failure due to the lack of consistent inspection for damage.

Our website stands as the go-to online destination for OEM Subaru Forester Brake Line. With complete lines of genuine Subaru Forester Brake Line available at unbeatable market prices, we ensure top quality, reliability, and durability. Each part comes backed by the manufacturer's warranty, reinforcing your trust in our offerings.

Subaru Forester Brake Line Parts Questions & Experts Answers

- Q: How to inspect and replace flexible brake hoses and brake line on Subaru Forester?A:Inspect the flexible hoses connecting the steel brake lines to the front and back brakes for cracks, chafing, leaks, blisters or any other form of damage at around every half year. Using a flare nut wrench clean off hose ends and unscrew the metal tube nut. Pull out the retaining clip from the frame bracket and remove the hose mounting bolt on the strut bracket. Disconnect it from caliper and throw away sealing washers. Tighten banjo bolt after attaching new brake hose to caliper with new sealing washers. Ensure correct routing of hose without twisting them. When replacing brake lines, use steel brake lines instead of copper tubing used in making them. Flared tube ends could be attached to pre-fabricated lines that have fixed fittings using a pipe bender that is meant for bending tubes. The new line should be held in place by original brackets and allowed adequate clearance between hot/moving parts. Finally, check master cylinder fluid level upon installation, top up if necessary fill brake system with bleed fluid then you can test brakes before normal operation resumes since it's mandatory to do so.

Related Subaru Forester Parts

Browse by Year

2025 Brake Line 2024 Brake Line 2023 Brake Line 2022 Brake Line 2021 Brake Line 2020 Brake Line 2019 Brake Line 2018 Brake Line 2017 Brake Line 2016 Brake Line 2015 Brake Line 2014 Brake Line 2013 Brake Line 2012 Brake Line 2011 Brake Line 2010 Brake Line 2009 Brake Line 2008 Brake Line 2007 Brake Line 2006 Brake Line 2005 Brake Line 2004 Brake Line 2003 Brake Line 2002 Brake Line 2001 Brake Line 2000 Brake Line 1999 Brake Line 1998 Brake Line