×

- Hello

- Login or Register

- Quick Links

- Live Chat

- Track Order

- Parts Availability

- RMA

- Help Center

- Contact Us

- Shop for

- Subaru Parts

- Subaru Accessories

My Garage

My Account

Cart

Genuine Subaru Forester Piston

Engine Pistons- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

24 Pistons found

Subaru Forester Piston Set Right Std A

Part Number: 12013AB650$67.48 MSRP: $97.80You Save: $30.32 (31%)Ships in 1-3 Business DaysSubaru Forester Piston Set Right Std B

Part Number: 12013AB660$67.48 MSRP: $97.80You Save: $30.32 (31%)

Subaru Forester Piston Set RH

Part Number: 12013AB250$79.27 MSRP: $114.88You Save: $35.61 (31%)Ships in 1-3 Business Days

Subaru Forester Piston Set RH OS0.25

Part Number: 12013AB550$65.35 MSRP: $94.72You Save: $29.37 (32%)Ships in 1-3 Business Days

Subaru Forester Piston Set RH

Part Number: 12013AB260$79.27 MSRP: $114.88You Save: $35.61 (31%)Ships in 1-3 Business Days

Subaru Forester Piston Set RH

Part Number: 12013AB270$79.27 MSRP: $114.88You Save: $35.61 (31%)Ships in 1-3 Business Days

Subaru Forester Piston Set Right OS0.50

Part Number: 12013AB680$67.48 MSRP: $97.80You Save: $30.32 (31%)Ships in 1-3 Business DaysSubaru Forester Piston Set Os 0.25

Part Number: 12006AE530$82.95 MSRP: $120.22You Save: $37.27 (31%)Ships in 1-3 Business DaysSubaru Forester Piston Set Std B

Part Number: 12006AE520$82.95 MSRP: $120.22You Save: $37.27 (31%)Ships in 1-3 Business DaysSubaru Forester Piston Set Std A

Part Number: 12006AE510$82.95 MSRP: $120.22You Save: $37.27 (31%)Ships in 1-3 Business DaysSubaru Forester Piston Set Right OS0.25

Part Number: 12013AB670$67.48 MSRP: $97.80You Save: $30.32 (31%)Ships in 1-3 Business DaysSubaru Forester Piston Set Os 0.50

Part Number: 12006AE540$82.95 MSRP: $120.22You Save: $37.27 (31%)Ships in 1-3 Business DaysSubaru Forester PISTON SET OS 0.50

Part Number: 12006AE660$87.07 MSRP: $126.18You Save: $39.11 (31%)Ships in 1-2 Business DaysSubaru Forester PISTON SET OS 0.25

Part Number: 12006AE650$87.07 MSRP: $126.18You Save: $39.11 (31%)Ships in 1-2 Business DaysSubaru Forester PISTON SET STD A

Part Number: 12006AE630$87.07 MSRP: $126.18You Save: $39.11 (31%)Ships in 1-2 Business DaysSubaru Forester PISTON SET STD B

Part Number: 12006AE640$87.07 MSRP: $126.18You Save: $39.11 (31%)Ships in 1-2 Business DaysSubaru Forester Piston Set RH Std B

Part Number: 12013AB540$65.35 MSRP: $94.72You Save: $29.37 (32%)Ships in 1-3 Business DaysSubaru Forester Piston Set RH OS0.50

Part Number: 12013AB560$65.35 MSRP: $94.72You Save: $29.37 (32%)Ships in 1-3 Business DaysSubaru Forester Piston Set RH Std A

Part Number: 12013AB530$65.35 MSRP: $94.72You Save: $29.37 (32%)

| Page 1 of 2 |Next >

1-20 of 24 Results

Subaru Forester Piston

Our website stands as the go-to online destination for OEM Subaru Forester Piston. With complete lines of genuine Subaru Forester Piston available at unbeatable market prices, we ensure top quality, reliability, and durability. Each part comes backed by the manufacturer's warranty, reinforcing your trust in our offerings.

Subaru Forester Piston Parts Questions & Experts Answers

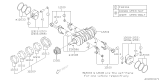

- Q: How should piston ring end gaps, piston pin cir clips, and pistons be correctly installed on Subaru Forester?A:Align the end gaps of the piston rings at a proper distance apart and replace the piston pin cir clips on the inner piston pin bore groove of each piston securely with the piston positioned in a way that the cir clip is placed in the groove with reference to the crankcase service hole. Wipe some of the fresh engine oil on the skirt and the rings and after that slide a piston ring compressor over the number one piston keeping the skirt about 1-inch sticking out to help you as you compress the rings as tight as possible. Slowly turn the Crankshaft clockwise until the number one and two connecting rods are vertically aligned at B.D.C with the center of the cylinder. Move the number one piston into the cylinder very carefully with the markup on the crown of the piston facing forward in the engine, then apply a light impact with your hand on the side of the ring compressor where it is in contact with the crankcase. People should fit the wooden/plastic hammer handle on the piston and push the piston into the cylinder while keeping the ring compressor on to ensure the piston rings do not flop out. Should resistance be encountered while resuscitating a patient, stop and look for the cause apart from pushing the piston. Advance the piston in until the piston pin bore and the small end of the connecting rod is perfectly aligned with the service hole, by using fabricated alignment tool. Unscrew the piston pin and apply a thin film of clean engine oil on the piston pin followed by sliding it through the service hole to the piston and connecting rod, should there be resistance align the new pin. Next, because of the outer cir clip, a new one should be fitted in the piston pin bore groove carefully so that it should not be misplaced as it will lead to serious damage to the engine. Perform the same steps for the number two piston, and put the service hole plug gaskets with RTV sealant and tighten them. While cranking the engine with the crankshaft snout down, turn the crankshaft until the number three & four connecting rods are at BDC, and repeat the piston & pin installation for these pistons. Last of all, RTV sealant should be applied to the service hole plug and cover gaskets, and after that, the plug and cover screws must be tightened.