×

- Hello

- Login or Register

- Quick Links

- Live Chat

- Track Order

- Parts Availability

- RMA

- Help Center

- Contact Us

- Shop for

- Subaru Parts

- Subaru Accessories

My Garage

My Account

Cart

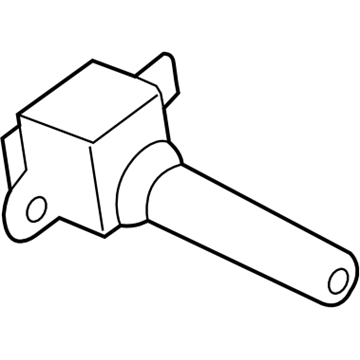

Genuine Subaru Ignition Coil

Ignition Coil Resistor- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

69 Ignition Coils found

Product Specifications

Product Specifications- Other Name: Coil Assembly-Ignition; Ignition Coil

- Replaces: 22433AA70A, 22433AA70B

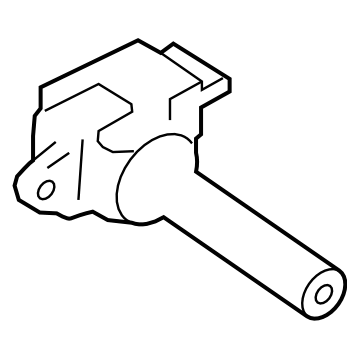

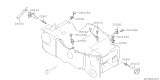

Subaru Ignition Coil Assembly

Part Number: 22433AA681$103.02 MSRP: $149.30You Save: $46.28 (31%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Coil Assembly-Ignition; Ignition Coil

- Replaced by: 22433AA682

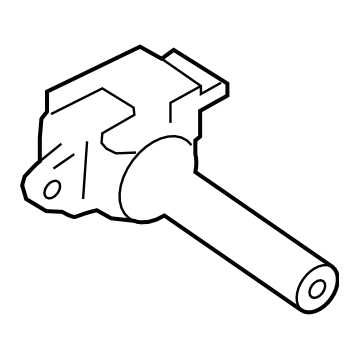

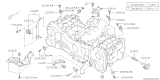

Subaru Ignition Coil Assembly

Part Number: 22433AA691$114.77 MSRP: $166.33You Save: $51.56 (31%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Coil Assembly-Ignition; Ignition Coil

- Replaces: 22433AA690

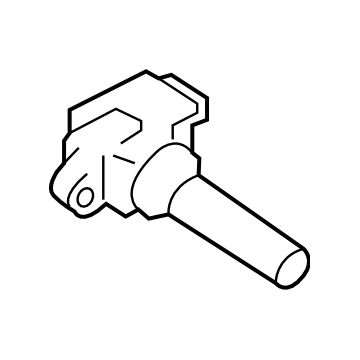

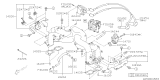

Subaru Ignition Coil Assembly

Part Number: 22433AA630$118.36 MSRP: $171.53You Save: $53.17 (31%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Coil Assembly-Ignition; Ignition Coil

Subaru Coil Assembly-Ign

Part Number: 22433AA770$155.13 MSRP: $226.80You Save: $71.67 (32%)Ships in 1-3 Business Days Product Specifications

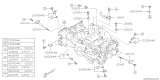

Product Specifications- Other Name: Coil Assembly-Ignition

- Replaced by: 22433AA542

Subaru Ignition Coil Assembly

Part Number: 22433AA612$142.79 MSRP: $208.75You Save: $65.96 (32%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Coil Assembly-Ignition; Ignition Coil

- Replaced by: 22433AA613

- Replaces: 22433AA611, 22433AA610

Subaru Ignition Coil Assembly

Part Number: 22433AA602$117.24 MSRP: $169.92You Save: $52.68 (31%)Ships in 1-3 Business DaysProduct Specifications- Other Name: Coil On Plug (COP) Ignition Coil; Ignition Coil

- Replaces: 22433AA600, 22433AA601

Subaru Ignition Coil Assembly

Part Number: 22433AA580$134.16 MSRP: $194.43You Save: $60.27 (31%)Ships in 1-3 Business DaysProduct Specifications- Other Name: Coil Assembly-Ignition; Ignition Coil

- Replaces: 22433AA500, 22433AA50A, 22433AA58A

Subaru Ignition Coil Assembly C0C4U6

Part Number: 22433AA590$137.87 MSRP: $199.82You Save: $61.95 (31%)Product Specifications- Other Name: Coil Assembly-Ignition; Ignition Coil

Subaru Ignition Coil Assembly

Part Number: 22433AA652$104.14 MSRP: $150.93You Save: $46.79 (31%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Coil Assembly-Ignition; Ignition Coil

- Replaces: 22433AA651, 22433AA650

Subaru Ignition Coil Assembly

Part Number: 22433AA540$87.39 MSRP: $126.65You Save: $39.26 (31%)Ships in 1-3 Business DaysProduct Specifications- Other Name: Coil Assembly-Ignition

- Replaced by: 22433AA542

Subaru Ignition Coil Assembly

Part Number: 22433AA421$89.09 MSRP: $129.12You Save: $40.03 (31%)Ships in 1-3 Business DaysProduct Specifications- Other Name: Coil Assembly-Ignition

- Replaced by: 22433AA561

Subaru Ignition Coil Assembly

Part Number: 22433AA621$123.53 MSRP: $179.03You Save: $55.50 (31%)Ships in 1-3 Business DaysProduct Specifications- Other Name: Coil Assembly-Ignition; Ignition Coil

- Replaces: 22433AA620

Subaru Ignition Coil Assembly

Part Number: 22433AA441$87.64 MSRP: $127.02You Save: $39.38 (31%)Ships in 1-3 Business DaysProduct Specifications- Other Name: Coil Assembly-Ignition

- Replaced by: 22433AA531

Subaru Ignition Coil Assembly

Part Number: 22433AA500$134.16 MSRP: $194.43You Save: $60.27 (31%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Coil Assembly-Ignition

- Replaced by: 22433AA580

Subaru Ignition Coil Assembly

Part Number: 22433AA730$107.43 MSRP: $155.70You Save: $48.27 (31%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Coil Assembly-Ignition; Ignition Coil

Subaru Ignition Coil Assembly

Part Number: 22433AA67B$115.58 MSRP: $167.50You Save: $51.92 (31%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Coil Assembly-Ignition; Ignition Coil

- Replaces: 22433AA67A

Subaru Coil Assembly Ignition

Part Number: 22433AA760$129.93 MSRP: $188.30You Save: $58.37 (31%)Ships in 1-3 Business DaysProduct Specifications- Other Name: Coil Ay Ignition

- Product Specifications

- Other Name: Coil Assembly-Ignition

- Replaced by: 22433AA700

| Page 1 of 4 |Next >

1-20 of 69 Results

Subaru Ignition Coil

Spark plugs require tremendous amounts of electricity to flash-and that's exactly what Subaru ignition coil provides. When the time comes that you'll have to replace that Subaru ignition coil of yours, make sure you get a replacement component that's built to give you lasting service. This ensures that your new Subaru ignition coil will fit and function just like your old component. It also guarantees that the Subaru ignition coil you're getting is one that you can easily install in your car, without requiring any product or ignition modifications.

Subaru Ignition Coil Parts Questions & Experts Answers

- Q: How to check and replace the ignition coil on Subaru Forester?A:Non-turbocharged models can have their ignition coils' primary and secondary resistance checked. One has to remove the four-terminal connector from the coil and test the continuity between terminals 1 and 2 as well as between terminals 2 and 4 when checking for primary resistance. If the multimeter does not show any reading within a determined range, this signifies that it should be replaced. It is necessary to put an ohmmeter across a pair of spark plugs on each cylinder head, which are connected by pairs of HT leads along the Vee engine's top. If you receive readings out of range, replace your coil with another new one in stock. However, one cannot check these figures on turbocharged models per individual coil-over-plug unit. A defective spark or weak sparks from only one coil point to broken circuit or a bad coil respectively. To replace an ignition coil on non-turbocharged models disconnect negative battery terminal, detach electrical connector and spark plug wires from the coil, ease off mounting bolts for ignition coils and then proceed to screwing back new ones in reverse order they were removed; while replacing an ignition coil on turbocharged models remove negative battery terminal, remove electrical connector screws from window washer motor (left side), or ignitions coils (right side), unbolted retaining bolt of an ignition coil next removes it off by pulling straight up at its side from spark plug site,and then detach the coil unit from the spark plug by pulling it straight out to the side.

Related Subaru Parts

Browse by Model

Ascent Ignition Coil BRZ Ignition Coil Baja Ignition Coil Crosstrek Ignition Coil Forester Ignition Coil GL Series Ignition Coil Impreza Ignition Coil Impreza STI Ignition Coil Impreza WRX Ignition Coil Justy Ignition Coil Legacy Ignition Coil Loyale Ignition Coil Outback Ignition Coil SVX Ignition Coil Tribeca Ignition Coil WRX Ignition Coil WRX STI Ignition Coil XT Ignition Coil XV Crosstrek Ignition Coil