×

- Hello

- Login or Register

- Quick Links

- Live Chat

- Track Order

- Parts Availability

- RMA

- Help Center

- Contact Us

- Shop for

- Subaru Parts

- Subaru Accessories

My Garage

My Account

Cart

Genuine Subaru Outback Camshaft

Cam- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

84 Camshafts found

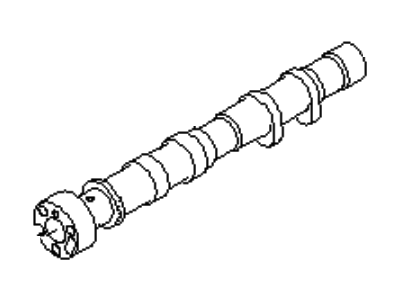

Subaru Outback CAMSHAFT Complete Intake LH

Part Number: 13037AA352$189.70 MSRP: $277.33You Save: $87.63 (32%)Ships in 1-3 Business Days

Subaru Outback CAMSHAFT Complete Exhaust LH

Part Number: 13052AA352$189.70 MSRP: $277.33You Save: $87.63 (32%)Ships in 1-3 Business Days

Subaru Outback CAMSHAFT Complete Exhaust RH

Part Number: 13034AA352$189.70 MSRP: $277.33You Save: $87.63 (32%)Ships in 1-3 Business Days

Subaru Outback CAMSHAFT Complete RH

Part Number: 13020AA720$196.81 MSRP: $287.73You Save: $90.92 (32%)Ships in 1-3 Business DaysSubaru Outback CAMSHAFT Complete-Exhaust LH

Part Number: 13052AB220$251.02 MSRP: $366.98You Save: $115.96 (32%)Ships in 1-3 Business DaysSubaru Outback CAMSHAFT Complete-Int LH

Part Number: 13037AB220$251.02 MSRP: $366.98You Save: $115.96 (32%)Ships in 1-3 Business DaysSubaru Outback CAMSHAFT Complete Exhaust

Part Number: 13052AB031$250.91 MSRP: $366.83You Save: $115.92 (32%)Ships in 1-3 Business DaysSubaru Outback CAMSHAFT Complete Exhaust

Part Number: 13034AB031$250.91 MSRP: $366.83You Save: $115.92 (32%)Ships in 1-3 Business DaysSubaru Outback CAMSHAFT Cp-EXH LH

Part Number: 13052AB251$251.02 MSRP: $366.98You Save: $115.96 (32%)Ships in 1-3 Business DaysSubaru Outback CAMSHAFT Complete Intake

Part Number: 13037AB031$250.91 MSRP: $366.83You Save: $115.92 (32%)Ships in 1-3 Business DaysSubaru Outback CAMSHAFT Cp-EXH RH

Part Number: 13034AB251$251.02 MSRP: $366.98You Save: $115.96 (32%)Ships in 1-2 Business DaysSubaru Outback CAMSHAFT Complete-Int RH

Part Number: 13031AB220$251.02 MSRP: $366.98You Save: $115.96 (32%)Ships in 1-3 Business DaysSubaru Outback CAMSHAFT Complete RH

Part Number: 13020AA710$227.32 MSRP: $332.33You Save: $105.01 (32%)Ships in 1-3 Business DaysSubaru Outback CAMSHAFT Complete Intake RH

Part Number: 13031AA670$299.72 MSRP: $442.07You Save: $142.35 (33%)Ships in 1-3 Business DaysSubaru Outback CAMSHAFT Complete Intake

Part Number: 13031AB031$250.91 MSRP: $366.83You Save: $115.92 (32%)Ships in 1-3 Business DaysSubaru Outback CAMSHAFT Cp-Int LH

Part Number: 13037AB251$251.02 MSRP: $366.98You Save: $115.96 (32%)Ships in 1-3 Business DaysSubaru Outback CAMSHAFT Cp-Int RH

Part Number: 13031AB251$251.02 MSRP: $366.98You Save: $115.96 (32%)Ships in 1-3 Business DaysSubaru Outback CAMSHAFT Complete Exhaust LH

Part Number: 13052AA670$299.72 MSRP: $442.07You Save: $142.35 (33%)Ships in 1-3 Business DaysSubaru Outback CAMSHAFT Complete-Exhaust RH

Part Number: 13034AB220$251.02 MSRP: $366.98You Save: $115.96 (32%)Ships in 1-3 Business DaysSubaru Outback CAMSHAFT Complete LH

Part Number: 13022AA680$227.32 MSRP: $332.33You Save: $105.01 (32%)Ships in 1-3 Business Days

| Page 1 of 5 |Next >

1-20 of 84 Results

Subaru Outback Camshaft

Our website stands as the go-to online destination for OEM Subaru Outback Camshaft. With complete lines of genuine Subaru Outback Camshaft available at unbeatable market prices, we ensure top quality, reliability, and durability. Each part comes backed by the manufacturer's warranty, reinforcing your trust in our offerings.

Subaru Outback Camshaft Parts Questions & Experts Answers

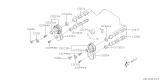

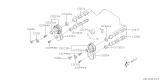

- Q: How to remove and install the Camshaft on Subaru Outback?A:Begin the removal of necessary elements by pulling the inner Timing Belt covers, crankshaft sprocket along with camshaft sprockets and timing belt. Take off the valve covers followed by removing Camshaft Position (CMP) sensor. For non-turbocharged engines, start gradually loosening rocker arm bolts and secure a special tool onto intake rocker arm assembly thereby locking it in place before lifting it from cylinder head. It is important to keep away all parts orderly. Remove the timing belt tensioner bracket as well as oil dipstick tube and camshaft end cap assembly. In case of turbocharged models, confirm if there are valve clearances then unplug VVT oil control solenoid connectors. These procedures also require you to take out timing belt tensioner bracket; WT oil flow control solenoid's oil pipe; gently loosen intake and exhaust camshaft cap bolts then store all parts in order. If need be, remove valve lifters. Examine lifters and rocker arms; camshaft lobes, journals, bearing caps, pivot points alongside metal-to-metal contact areas for any signs of wear or damage. Measure height of lobe on each camshaft journal's inside diameter and compare this with cambore size across every journal bore on camshafts' internal diameters accordingly replace components that generate more friction than what is needed. Apply lubricant intended for installation of camshafts journals plus lobes within anaerobic sealant added to the cap assembly at its end whereas install them together with rockers' assembly, seals of oil on shafts either side plus plugs at their ends for vehicles without any superchargers or turbochargers while put down valves caring about these ones cheaply bought through online stores right now on behalf of lubrication prior to fitting which has been made possible through proper tightening during manufacturing process as shown below: This means using some grease before fitting lifters so that there is less wear on these parts while installing cams followed by camshaft caps ending with seals near them. Check again whether valve clearances are set correctly. The next step is to insert connectors of VVT oil flow control solenoid. Have camshaft sprockets or actuators fixed and put timing belt then install valve covers afterwards. Finish the remaining installation steps, start up the engine and check whether there is any unusual noise or leaks of oil coming out from it.

Related Subaru Outback Parts

Browse by Year

2025 Camshaft 2024 Camshaft 2023 Camshaft 2022 Camshaft 2021 Camshaft 2020 Camshaft 2019 Camshaft 2018 Camshaft 2017 Camshaft 2016 Camshaft 2015 Camshaft 2014 Camshaft 2013 Camshaft 2012 Camshaft 2011 Camshaft 2010 Camshaft 2009 Camshaft 2008 Camshaft 2007 Camshaft 2006 Camshaft 2005 Camshaft 2004 Camshaft 2003 Camshaft 2002 Camshaft 2001 Camshaft 2000 Camshaft 1999 Camshaft 1998 Camshaft 1997 Camshaft 1996 Camshaft