×

- Hello

- Login or Register

- Quick Links

- Live Chat

- Track Order

- Parts Availability

- RMA

- Help Center

- Contact Us

- Shop for

- Subaru Parts

- Subaru Accessories

My Garage

My Account

Cart

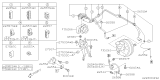

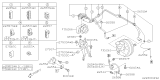

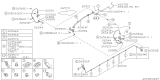

Genuine Subaru Impreza Brake Line

Brake Hose- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

54 Brake Lines found

Subaru Impreza Brake Hose Front LH

Part Number: 26540AE020$31.94 MSRP: $46.28You Save: $14.34 (31%)Ships in 1-3 Business Days

Subaru Impreza Brake Hose Front RH

Part Number: 26590AE001$31.94 MSRP: $46.28You Save: $14.34 (31%)Ships in 1-3 Business Days

Subaru Impreza Brake Pipe

Part Number: 26531AA020$19.99 MSRP: $28.97You Save: $8.98 (31%)Ships in 1-3 Business DaysSubaru Impreza BRAKE HOSE R LH

Part Number: 26541FN011$40.25 MSRP: $58.33You Save: $18.08 (31%)Ships in 1-2 Business DaysSubaru Impreza BRAKE HOSE R LH

Part Number: 26541FN070$43.96 MSRP: $63.72You Save: $19.76 (32%)Ships in 1-2 Business DaysSubaru Impreza BRAKE HOSE R RH

Part Number: 26541FN060$43.96 MSRP: $63.72You Save: $19.76 (32%)Ships in 1-2 Business DaysSubaru Impreza Brake Hose Rear Left Hand

Part Number: 26541FL05A$71.24 MSRP: $103.25You Save: $32.01 (31%)Subaru Impreza BRAKE HOSE F RH

Part Number: 26540FN001$33.51 MSRP: $48.57You Save: $15.06 (32%)Ships in 1-2 Business DaysSubaru Impreza BRAKE HOSE F LH

Part Number: 26540FN030$17.02 MSRP: $24.67You Save: $7.65 (32%)Ships in 1-2 Business DaysSubaru Impreza BRAKE HOSE F LH

Part Number: 26540FN011$33.51 MSRP: $48.57You Save: $15.06 (32%)Ships in 1-2 Business DaysSubaru Impreza BRAKE HOSE R RH

Part Number: 26541FN001$40.25 MSRP: $58.33You Save: $18.08 (31%)Ships in 1-2 Business DaysSubaru Impreza Brake Hose Front LH

Part Number: 26540FL05A$17.02 MSRP: $24.67You Save: $7.65 (32%)Ships in 1-2 Business DaysSubaru Impreza Brake Hose Front RH

Part Number: 26540FL04A$35.81 MSRP: $51.90You Save: $16.09 (31%)Ships in 1-2 Business DaysSubaru Impreza BRAKE HOSE R LH

Part Number: 26541FL150$71.24 MSRP: $103.25You Save: $32.01 (31%)Ships in 1-2 Business DaysSubaru Impreza BRAKE HOSE R RH

Part Number: 26541FL140$71.24 MSRP: $103.25You Save: $32.01 (31%)Ships in 1-2 Business DaysSubaru Impreza BRAKE HOSE F RH

Part Number: 26540FN020$35.81 MSRP: $51.90You Save: $16.09 (31%)Ships in 1-2 Business DaysSubaru Impreza Brake Hose Front LH

Part Number: 26590FG030$31.94 MSRP: $46.28You Save: $14.34 (31%)Ships in 1-3 Business DaysSubaru Impreza Brake Hose Rear RH

Part Number: 26591FJ000$38.33 MSRP: $55.55You Save: $17.22 (31%)Ships in 1-2 Business Days

| Page 1 of 3 |Next >

1-20 of 54 Results

Subaru Impreza Brake Line

Our website stands as the go-to online destination for OEM Subaru Impreza Brake Line. With complete lines of genuine Subaru Impreza Brake Line available at unbeatable market prices, we ensure top quality, reliability, and durability. Each part comes backed by the manufacturer's warranty, reinforcing your trust in our offerings.

Subaru Impreza Brake Line Parts Questions & Experts Answers

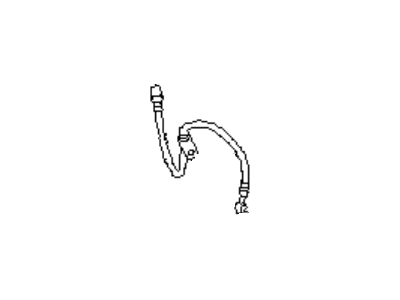

- Q: How Often Should Flexible Hoses Connecting Steel Brake Lines Be Inspected on Subaru Impreza?A:Every six months, the flexible hoses which connect the steel brake lines with the front and rear brake assemblies should be inspected for cracks, chafing of the outer cover, leaks, blisters and other damage. Clean all dirt away from the ends of the hose, unscrew the metal tube nut with a flare nut wrench, pull the retaining clip straight out from the hose fitting at the frame bracket and remove the hose from the bracket. On front hoses, remove the hose mounting bolt from the bracket on the strut. Disconnect the hose from the caliper and discard the sealing washers. Attach the new brake hose to the caliper using new sealing washers. Tighten the brake hose banjo bolt and route correctly without twisting. When replacing brake lines, use the correct parts and purchase steel brake lines from a dealer parts department or auto parts store. Prefabricated brake line, with the tube ends already flared and fittings installed, is available at auto parts stores and dealer parts departments. These lines can be bent to the proper shapes using a tubing bender. Make sure the line is supported in the original brackets and has plenty of clearance between moving or hot components. After installation, check the master cylinder fluid level and add fluid as necessary. Bleed the brake system and test the brakes carefully before placing the vehicle into normal operation.

Related Subaru Impreza Parts

Browse by Year

2025 Brake Line 2024 Brake Line 2023 Brake Line 2022 Brake Line 2021 Brake Line 2020 Brake Line 2019 Brake Line 2018 Brake Line 2017 Brake Line 2016 Brake Line 2015 Brake Line 2014 Brake Line 2013 Brake Line 2012 Brake Line 2011 Brake Line 2010 Brake Line 2009 Brake Line 2008 Brake Line 2007 Brake Line 2006 Brake Line 2005 Brake Line 2004 Brake Line 2003 Brake Line 2002 Brake Line 2001 Brake Line 2000 Brake Line 1999 Brake Line 1998 Brake Line 1997 Brake Line 1996 Brake Line 1995 Brake Line 1994 Brake Line 1993 Brake Line