×

- Hello

- Login or Register

- Quick Links

- Live Chat

- Track Order

- Parts Availability

- RMA

- Help Center

- Contact Us

- Shop for

- Subaru Parts

- Subaru Accessories

My Garage

My Account

Cart

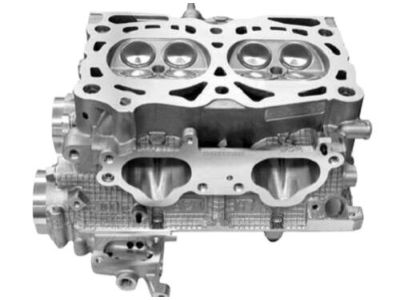

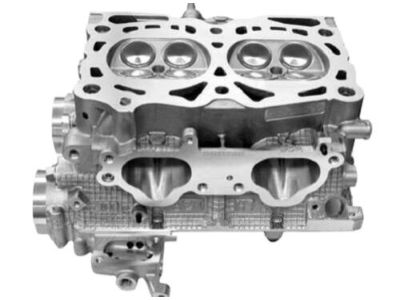

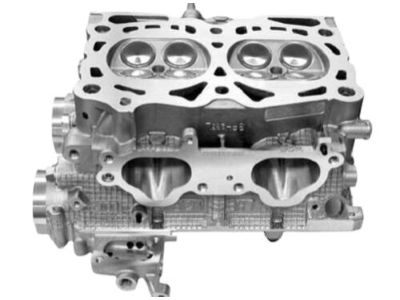

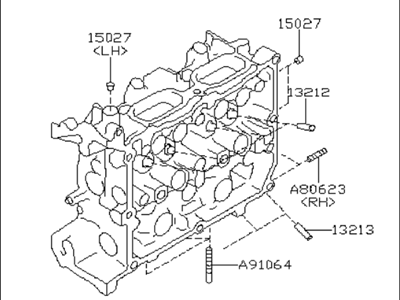

Genuine Subaru Impreza Cylinder Head

Head- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

51 Cylinder Heads found

Subaru Impreza Cylinder Head Assembly Left

Part Number: 11063AB480$607.54 MSRP: $896.08You Save: $288.54 (33%)Ships in 1-2 Business Days

Subaru Impreza Cylinder Head Assembly Left

Part Number: 11063AB250$664.59 MSRP: $980.22You Save: $315.63 (33%)Ships in 1-3 Business Days

Subaru Impreza Cylinder Head Assembly Right

Part Number: 11039AC320$607.54 MSRP: $896.08You Save: $288.54 (33%)Ships in 1-3 Business Days

Subaru Impreza Cylinder Head Assembly Right

Part Number: 11039AC340$664.59 MSRP: $980.22You Save: $315.63 (33%)Ships in 1-3 Business Days

Subaru Impreza Cylinder Head Assembly

Part Number: 11039AC020$624.38 MSRP: $920.92You Save: $296.54 (33%)

Subaru Impreza Cylinder Head Assembly Right

Part Number: 11039AB820$639.07 MSRP: $942.58You Save: $303.51 (33%)Ships in 1-3 Business Days

Subaru Impreza Cylinder Head Assembly Right

Part Number: 11039AB910$660.27 MSRP: $973.85You Save: $313.58 (33%)Ships in 1-3 Business DaysSubaru Impreza Engine Cylinder Head Right

Part Number: 11039AB361$618.47 MSRP: $912.20You Save: $293.73 (33%)Ships in 1-3 Business DaysSubaru Impreza Cylinder Head Assembly

Part Number: 11039AC070$662.70 MSRP: $977.43You Save: $314.73 (33%)Ships in 1-2 Business DaysSubaru Impreza Cylinder Head Assembly Left

Part Number: 11063AA841$622.03 MSRP: $917.45You Save: $295.42 (33%)Ships in 1-3 Business DaysSubaru Impreza HEAD ASSY-CYL RH

Part Number: 11039AC62B$507.16 MSRP: $748.02You Save: $240.86 (33%)Ships in 1-2 Business DaysSubaru Impreza Cylinder Head Assembly Right

Part Number: 11039AB650$622.03 MSRP: $917.45You Save: $295.42 (33%)Ships in 1 Business DaySubaru Impreza HEAD ASSY-CYL LH

Part Number: 11063AB90B$507.14 MSRP: $748.00You Save: $240.86 (33%)Ships in 1-2 Business DaysSubaru Impreza HEAD ASSY-CYL RH

Part Number: 11039AC810$552.28 MSRP: $814.57You Save: $262.29 (33%)Ships in 1-2 Business DaysSubaru Impreza Cylinder Head Assembly Left

Part Number: 11063AB280$687.04 MSRP: $1013.33You Save: $326.29 (33%)Ships in 1-3 Business DaysSubaru Impreza HEAD ASSY-CYL LH

Part Number: 11063AC110$552.28 MSRP: $814.57You Save: $262.29 (33%)Ships in 1-2 Business DaysSubaru Impreza Cylinder Head Assembly Left

Part Number: 11063AB120$622.03 MSRP: $917.45You Save: $295.42 (33%)Ships in 1 Business DaySubaru Impreza HEAD ASSY-CYL RH

Part Number: 11039AC830$639.25 MSRP: $942.85You Save: $303.60 (33%)Ships in 1-2 Business DaysSubaru Impreza HEAD ASSY-CYL LH

Part Number: 11063AC130$653.37 MSRP: $963.67You Save: $310.30 (33%)Ships in 1-2 Business DaysSubaru Impreza Cylinder Head Assembly Left

Part Number: 11063AB310$681.80 MSRP: $1005.60You Save: $323.80 (33%)Ships in 1-3 Business Days

| Page 1 of 3 |Next >

1-20 of 51 Results

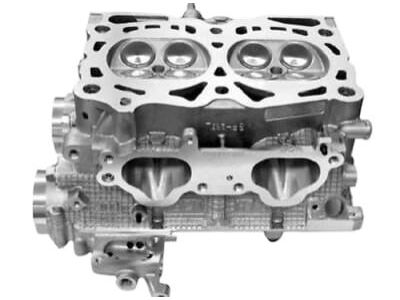

Subaru Impreza Cylinder Head

Our website stands as the go-to online destination for OEM Subaru Impreza Cylinder Head. With complete lines of genuine Subaru Impreza Cylinder Head available at unbeatable market prices, we ensure top quality, reliability, and durability. Each part comes backed by the manufacturer's warranty, reinforcing your trust in our offerings.

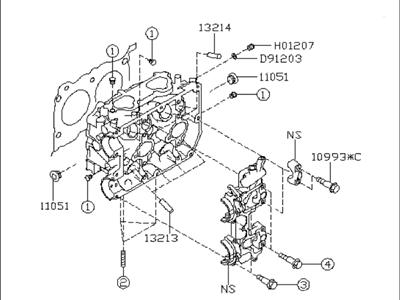

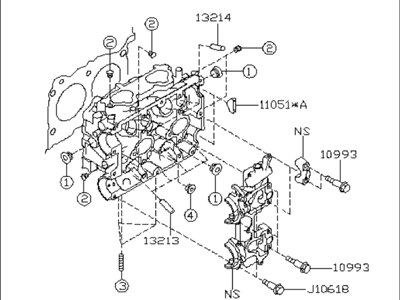

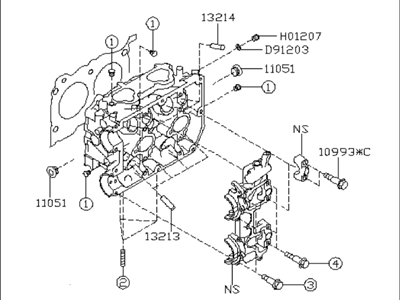

Subaru Impreza Cylinder Head Parts Questions & Experts Answers

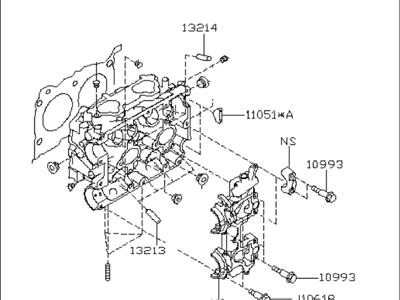

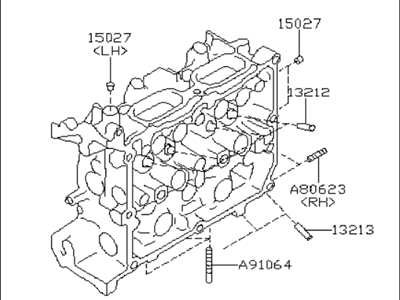

- Q: How to removal and installation of cylinder heads on Subaru Impreza?A:Relieve the fuel pressure. Disconnect the cable from the negative terminal of the battery. Drain the cooling system and remove the spark plugs. Remove the Timing Belt, Camshaft sprockets, and inner timing belt covers. Remove the camshafts. Disconnect the Exhaust Manifold from the cylinder heads. Apply penetrating oil to the fasteners before beginning the procedure and allow it to soak in for a while. Remove the Intake Manifold. Remove any hoses or brackets bolted to the cylinder heads. Loosen the cylinder head bolts in the reverse order of the tightening sequence. Remove the cylinder heads and the old gaskets. The block and cylinder heads are aluminum. Do not pry between the cylinder heads and the crankcase as damage to the gasket seating surfaces may result. Instead, use a soft-faced hammer to tap the cylinder heads and break the gasket seat. Cylinder head disassembly and inspection procedures should be performed by a qualified automotive machine shop. Installation: Clean the gasket mating surfaces of the cylinder heads and crankcase with lacquer thinner or acetone. They must be clean and oil-free. Install the cylinder head gasket onto the cylinder head locating dowels on the engine block. Install the cylinder head(s). Lubricate the bolt threads and washers with engine oil, then install them hand-tight. Use a torque-angle meter or mark the bolt heads with white paint and tighten the bolts. The remainder of the installation is the reverse of removal.

Related Subaru Impreza Parts

Browse by Year

2025 Cylinder Head 2024 Cylinder Head 2023 Cylinder Head 2022 Cylinder Head 2021 Cylinder Head 2020 Cylinder Head 2019 Cylinder Head 2018 Cylinder Head 2017 Cylinder Head 2016 Cylinder Head 2015 Cylinder Head 2014 Cylinder Head 2013 Cylinder Head 2012 Cylinder Head 2011 Cylinder Head 2010 Cylinder Head 2009 Cylinder Head 2008 Cylinder Head 2007 Cylinder Head 2006 Cylinder Head 2005 Cylinder Head 2004 Cylinder Head 2003 Cylinder Head 2002 Cylinder Head 2001 Cylinder Head 2000 Cylinder Head 1999 Cylinder Head 1998 Cylinder Head 1997 Cylinder Head 1996 Cylinder Head 1995 Cylinder Head 1994 Cylinder Head 1993 Cylinder Head