×

- Hello

- Login or Register

- Quick Links

- Live Chat

- Track Order

- Parts Availability

- RMA

- Help Center

- Contact Us

- Shop for

- Subaru Parts

- Subaru Accessories

My Garage

My Account

Cart

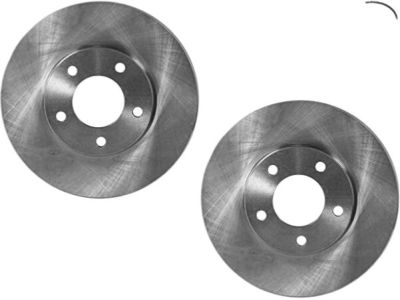

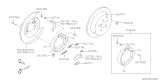

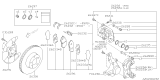

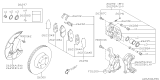

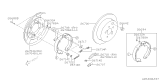

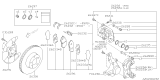

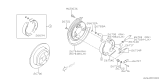

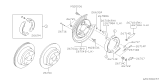

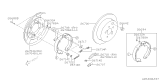

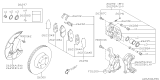

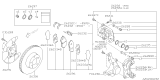

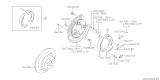

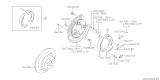

Genuine Subaru Legacy Brake Disc

Disc Rotor- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

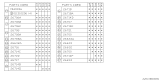

34 Brake Discs found

Subaru Legacy Brake Disc Rear

Part Number: 26700AL03A$66.01 MSRP: $95.67You Save: $29.66 (31%)Ships in 1-2 Business Days

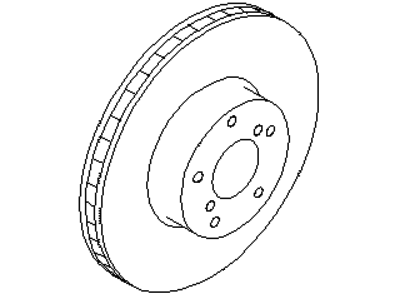

Subaru Legacy Brake Disc Front

Part Number: 26300AG01A$67.85 MSRP: $98.33You Save: $30.48 (31%)Ships in 1-3 Business Days

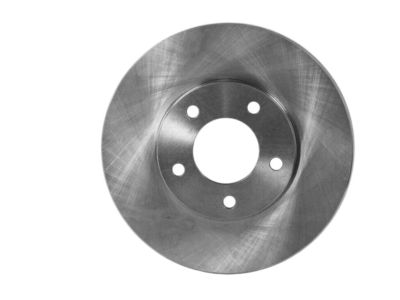

Subaru Legacy Brake Disc Front

Part Number: 26300AL03A$81.08 MSRP: $117.50You Save: $36.42 (31%)Ships in 1-3 Business Days

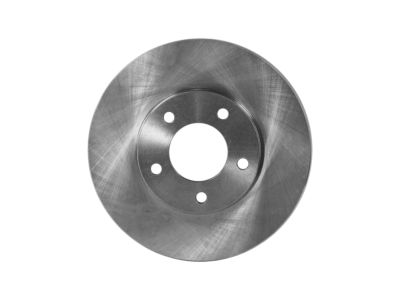

Subaru Legacy Brake Disc Rear

Part Number: 26700AL010$72.97 MSRP: $105.75You Save: $32.78 (31%)Ships in 1-3 Business Days

Subaru Legacy Brake Disc Front

Part Number: 26300AG02A$72.45 MSRP: $105.00You Save: $32.55 (31%)Ships in 1-3 Business Days

Subaru Legacy Brake Disc F16

Part Number: 26300AL000$69.68 MSRP: $100.98You Save: $31.30 (31%)Ships in 1-3 Business Days

Subaru Legacy Brake Disc Rear V

Part Number: 26700AJ010$62.68 MSRP: $90.83You Save: $28.15 (31%)Ships in 1-3 Business Days

Subaru Legacy Brake Disk Front

Part Number: 26300AG001$62.62 MSRP: $90.75You Save: $28.13 (31%)Ships in 1-3 Business Days

Subaru Legacy Brake Disc Rear

Part Number: 26700AG01B$62.07 MSRP: $89.95You Save: $27.88 (31%)Ships in 1-3 Business Days

Subaru Legacy BRK Disk Rear

Part Number: 26700AE081$68.16 MSRP: $98.78You Save: $30.62 (31%)Ships in 1 Business Day

Subaru Legacy Brake Disc Rear S

Part Number: 26700AJ00A$62.66 MSRP: $90.82You Save: $28.16 (32%)Ships in 1-3 Business Days

Subaru Legacy Brake Disk Front

Part Number: 26310AA092$57.44 MSRP: $83.25You Save: $25.81 (31%)Ships in 1-3 Business Days

Subaru Legacy Brake Disk Front

Part Number: 26300AL04A$80.47 MSRP: $116.62You Save: $36.15 (31%)Ships in 1-3 Business Days

Subaru Legacy Brake Disc Front

Part Number: 26300AE02B$72.45 MSRP: $105.00You Save: $32.55 (31%)Ships in 1-2 Business Days

Subaru Legacy Brake Disk Rear

Part Number: 26310AA051$66.21 MSRP: $95.95You Save: $29.74 (31%)Ships in 1-3 Business Days

Subaru Legacy Brake Disc Rear

Part Number: 26700AE04A$78.17 MSRP: $113.28You Save: $35.11 (31%)Ships in 1-3 Business Days

Subaru Legacy Brake Disc Rear

Part Number: 26700AE04B$78.17 MSRP: $113.28You Save: $35.11 (31%)Ships in 1-2 Business DaysSubaru Legacy Brake Disc F

Part Number: 26300AN00A$89.13 MSRP: $129.17You Save: $40.04 (31%)Ships in 1-2 Business DaysSubaru Legacy Brake Disk Front

Part Number: 26300AG000$62.62 MSRP: $90.75You Save: $28.13 (31%)Ships in 1-3 Business DaysSubaru Legacy Brake Disk Front

Part Number: 26310AA032$58.62 MSRP: $84.95You Save: $26.33 (31%)Ships in 1-3 Business Days

| Page 1 of 2 |Next >

1-20 of 34 Results

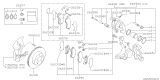

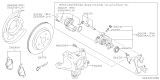

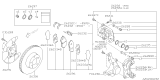

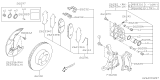

Subaru Legacy Brake Disc

Our website stands as the go-to online destination for OEM Subaru Legacy Brake Disc. With complete lines of genuine Subaru Legacy Brake Disc available at unbeatable market prices, we ensure top quality, reliability, and durability. Each part comes backed by the manufacturer's warranty, reinforcing your trust in our offerings.

Subaru Legacy Brake Disc Parts Questions & Experts Answers

- Q: How to inspect and replace brake discs on Subaru Legacy?A:Start by loosening the wheel lug nuts and raising the vehicle to remove, if necessary, inspect your brake discs and put them back. Stabilize the disc on top of hub flange using lug nuts after removing the wheel. If working on rear disc, release parking brakes. Take off a Brake Caliper without disconnecting a hose pipe for that braking system and use wire to suspend it safely. Visually check the surface of the brake rotors for scored marks or damage-deep scoring will require the rotor to be removed and refinished by a machine shop. In addition, examine both sides of a rotor and assess its runout using dial indicator. If the runout exceeds specified limits one may need machining. Even when indicator reading is within limits it is still recommended to surface discs again in order to get smooth finishing. If there's no resurfacing involved, then with circular movement rub emery cloth or sandpaper against glazed surfaces until it's gone or try remachining them. Use a micrometer to measure thickness of rotor making sure that it remains above minimum thickness usually cast or stamped into it (rotor). To have this detached, remove relevant bolts unscrewing caliper support bracket after which slide out disk from hub applying bolts where necessary.There are two types: solid one-piece (non-vented) and vented (two-piece). Inspect parking brakes shoes for rear disks.Most important step here is thoroughly cleaning all parts plus installation of disk, calipers support brackets, brake pads themselves as well as tightening required bolts.Finally install your wheels back, lower your vehicle down and tighten lug nuts.Press down pedal so that pads can touch rotor then test braking system before driving away, however if you disconnected your brakeline bleeding is desired.Notes coould be made only in case hose has been disconnected because of necessity to bleed it.

Related Subaru Legacy Parts

Browse by Year

2025 Brake Disc 2024 Brake Disc 2023 Brake Disc 2022 Brake Disc 2021 Brake Disc 2020 Brake Disc 2019 Brake Disc 2018 Brake Disc 2017 Brake Disc 2016 Brake Disc 2015 Brake Disc 2014 Brake Disc 2013 Brake Disc 2012 Brake Disc 2011 Brake Disc 2010 Brake Disc 2009 Brake Disc 2008 Brake Disc 2007 Brake Disc 2006 Brake Disc 2005 Brake Disc 2004 Brake Disc 2003 Brake Disc 2002 Brake Disc 2001 Brake Disc 2000 Brake Disc 1999 Brake Disc 1998 Brake Disc 1997 Brake Disc 1996 Brake Disc 1995 Brake Disc 1994 Brake Disc 1993 Brake Disc 1992 Brake Disc 1991 Brake Disc 1990 Brake Disc