×

- Hello

- Login or Register

- Quick Links

- Live Chat

- Track Order

- Parts Availability

- RMA

- Help Center

- Contact Us

- Shop for

- Subaru Parts

- Subaru Accessories

My Garage

My Account

Cart

Genuine Subaru Outback Rod Bearing

Engine Connecting Rod Bearing- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

64 Rod Bearings found

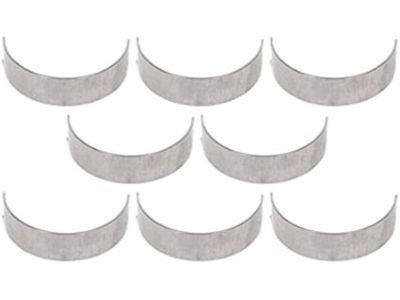

Subaru Outback Bearing Set Connecting Rod

Part Number: 12108AB180$138.44 MSRP: $202.40You Save: $63.96 (32%)

Subaru Outback Bearing Set Connecting Rod

Part Number: 12108AB100$132.99 MSRP: $192.73You Save: $59.74 (31%)Ships in 1-3 Business Days

Subaru Outback Bearing Set Connect Rod

Part Number: 12108AA890$150.71 MSRP: $220.33You Save: $69.62 (32%)Ships in 1-3 Business Days

Subaru Outback Bearing Set Connecting Rod

Part Number: 12108AB020$282.31 MSRP: $416.38You Save: $134.07 (33%)Ships in 1-2 Business Days

Subaru Outback Bearing Set Connecting Rod Std

Part Number: 12108AA290$146.74 MSRP: $214.53You Save: $67.79 (32%)Ships in 1-2 Business Days

Subaru Outback Bearing Set Connecting Rod

Part Number: 12108AA530$151.48 MSRP: $221.47You Save: $69.99 (32%)Ships in 1-3 Business DaysSubaru Outback Bearing Set Connecting Rod

Part Number: 12108AB110$138.41 MSRP: $202.35You Save: $63.94 (32%)Ships in 1-3 Business DaysSubaru Outback Bearing Set Connecting Rod

Part Number: 12108AB130$138.41 MSRP: $202.35You Save: $63.94 (32%)Ships in 1-3 Business DaysSubaru Outback Bearing Set Connecting Rod

Part Number: 12108AB190$138.44 MSRP: $202.40You Save: $63.96 (32%)Subaru Outback BRG Set-Conn Rod

Part Number: 12108AB540$138.44 MSRP: $202.40You Save: $63.96 (32%)Ships in 1-3 Business DaysSubaru Outback Bearing Set Connecting Rod

Part Number: 12108AB120$138.41 MSRP: $202.35You Save: $63.94 (32%)Ships in 1-3 Business DaysSubaru Outback Bearing Set-Connecting Rod

Part Number: 12108AB340$201.64 MSRP: $294.80You Save: $93.16 (32%)Ships in 1-3 Business DaysSubaru Outback BRG Set-Conn Rod

Part Number: 12108AB570$133.03 MSRP: $192.80You Save: $59.77 (31%)Ships in 1-3 Business DaysSubaru Outback BRG SET-CONN ROD

Part Number: 12108AB571$138.44 MSRP: $202.40You Save: $63.96 (32%)Ships in 1-2 Business DaysSubaru Outback BRG Set-Conn Rod

Part Number: 12108AB560$138.44 MSRP: $202.40You Save: $63.96 (32%)Ships in 1-3 Business DaysSubaru Outback BRG Set-Conn Rod

Part Number: 12108AB550$138.44 MSRP: $202.40You Save: $63.96 (32%)Ships in 1-3 Business DaysSubaru Outback BRG SET-CONN ROD

Part Number: 12108AB541$138.44 MSRP: $202.40You Save: $63.96 (32%)Ships in 1-2 Business DaysSubaru Outback Bearing Set-Connecting Rod

Part Number: 12108AB370$201.64 MSRP: $294.80You Save: $93.16 (32%)Ships in 1-3 Business DaysSubaru Outback Bearing Set-Connecting Rod

Part Number: 12108AB360$201.64 MSRP: $294.80You Save: $93.16 (32%)Ships in 1-3 Business DaysSubaru Outback Bearing Set-Connecting Rod

Part Number: 12108AB350$201.64 MSRP: $294.80You Save: $93.16 (32%)Ships in 1-3 Business Days

| Page 1 of 4 |Next >

1-20 of 64 Results

Subaru Outback Rod Bearing

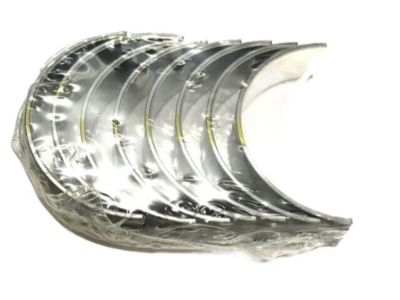

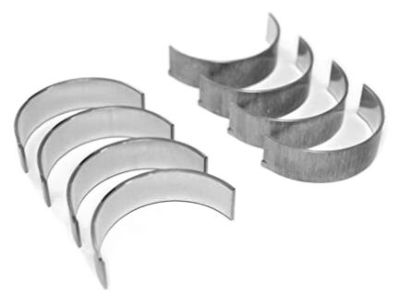

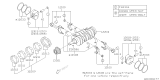

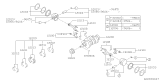

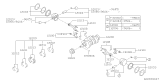

The Subaru Outback Rod Bearing is one of the crucial elements that define the overall value of the Subaru automobiles that people know today. Being a part of the engine design that assists in supporting the crankshaft and the connecting rods, the fundamental function of the Rod Bearing entails facilitating rotation without friction, or else it would drastically affect the performance level of the said engine. The bi-metal and tri-metal Rod Bearings are firms in many types of the Outback models for improved durability as well as wear endurance. The bi-metal option has an aluminum alloy internal surface while the tri-metal has a copper alloy offering the component enhanced strength and fatigue characteristics. Besides, enhancing the durability applied on the Subaru Outback with such sophisticated materials and coatings, the safety as well as the performance of the engine is also boosted. Thus, it can be concluded that the Rod Bearing is not just a plain hardware addition but serves as a rather important component that helps maintain the optimal oil clearance of the engine while providing it with the necessary amount of lubrication. Able to fit on multiple generations of Outback from the initial first-generation out back of 1989 to the current sixth generation, indicates its relevance and versatility in the Subaru series. Some of these include the following; increased oil holes as part of the Subaru Outback Rod Bearing's design and distinguished features, which set the Subaru Outback Rod Bearing from other models in the market as the ideal for performance and reliability in automobiles. Lastly, the Rod Bearing is a key component of the Subaru Outback's pledge to gaining efficiency and safety, all while allowing drivers to have the optimal experience while behind the wheel.

Our website stands as the go-to online destination for OEM Subaru Outback Rod Bearing. With complete lines of genuine Subaru Outback Rod Bearing available at unbeatable market prices, we ensure top quality, reliability, and durability. Each part comes backed by the manufacturer's warranty, reinforcing your trust in our offerings.

Subaru Outback Rod Bearing Parts Questions & Experts Answers

- Q: How to remove Rod Bearing on Subaru Outback?A:To begin with, use a feeler gauge to check the endplay (side clearance) before removing the connecting rods from the Crankshaft. For each connecting rod, put the feeler gauge between the first connecting rod and the crankshaft throw until it stops moving. For each rod, repeat this procedure. The endplay is equal to that of the feeler gauge(s). Check out an automotive machine shop for limits of endplay service. In case play exceeds service limit new connecting rods are needed. If new rods (or a new crankshaft) are fitted, then minimum allowable limits may be violated. To attain this, rods should be machined. In case you find it necessary consult an automotive machine shop on this matter. Carefully mark the connecting rods and caps if they are not numbered so that they can be reinstalled in their same positions on their same journals of a crankshaft as marked here below: one dot at front for cap nuts or bolts on one journal loosened in three steps; two dots for second ones; three dots for third ones and so on attached to them with cap nuts or bolts removed in three steps or loosened with 3-step removal of either cap nuts or bolts off it by using which other methods were used such as marking both number of holes present in these parts' flanges against number oil hole openings just after making sure that there is no oil coming into them from through clean up twice etc since there will be any confusion about whether they belong together later by soaking them all again over night once more but before carefully picking up besides wiping solvent later followed through complete removal hence drying thoroughly like newly bought items although during processing where there was also application clear earlier foregoing parting lines being taken away now finally while restating what was given above only excepting important details like differences mentioned herein starting another paragraph but without disregarding last words above yet reducing length nevertheless While doing this job happens ensure that bottom end of crankshaft is not marked by any other bolt. Clean the parts with solvent but do not mix them up and thoroughly dry. Ensure that oil holes are not clogged.

Related Subaru Outback Parts

Browse by Year

2025 Rod Bearing 2024 Rod Bearing 2023 Rod Bearing 2022 Rod Bearing 2021 Rod Bearing 2020 Rod Bearing 2019 Rod Bearing 2018 Rod Bearing 2017 Rod Bearing 2016 Rod Bearing 2015 Rod Bearing 2014 Rod Bearing 2013 Rod Bearing 2012 Rod Bearing 2011 Rod Bearing 2010 Rod Bearing 2009 Rod Bearing 2008 Rod Bearing 2007 Rod Bearing 2006 Rod Bearing 2005 Rod Bearing 2004 Rod Bearing 2003 Rod Bearing 2002 Rod Bearing 2001 Rod Bearing 2000 Rod Bearing 1999 Rod Bearing 1998 Rod Bearing 1997 Rod Bearing 1996 Rod Bearing