×

- Hello

- Login or Register

- Quick Links

- Live Chat

- Track Order

- Parts Availability

- RMA

- Help Center

- Contact Us

- Shop for

- Subaru Parts

- Subaru Accessories

My Garage

My Account

Cart

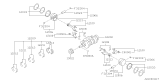

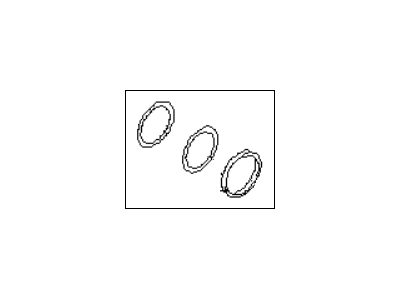

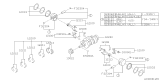

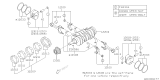

Genuine Subaru Outback Piston Ring Set

Piston Ring- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

51 Piston Ring Sets found

Subaru Outback Piston Ring Set

Part Number: 12033AB340$161.57 MSRP: $236.22You Save: $74.65 (32%)Ships in 1-3 Business Days

Subaru Outback Ring Set Piston

Part Number: 12033AC180$201.61 MSRP: $294.75You Save: $93.14 (32%)Ships in 1-3 Business Days

Subaru Outback Piston Ring Set Std

Part Number: 12033AA210$160.87 MSRP: $235.18You Save: $74.31 (32%)Ships in 1-3 Business Days

Subaru Outback Piston Ring Set

Part Number: 12033AB360$161.57 MSRP: $236.22You Save: $74.65 (32%)Ships in 1-3 Business Days

Subaru Outback Ring Set Piston

Part Number: 12033AC250$141.26 MSRP: $206.52You Save: $65.26 (32%)Ships in 1-3 Business DaysSubaru Outback Ring Set Piston

Part Number: 12033AC240$146.54 MSRP: $214.23You Save: $67.69 (32%)Ships in 1-2 Business DaysSubaru Outback Ring Set Piston

Part Number: 12033AC90A$43.42 MSRP: $62.93You Save: $19.51 (31%)Ships in 1-2 Business DaysSubaru Outback Piston Ring Set Std

Part Number: 12033AA760$178.10 MSRP: $260.38You Save: $82.28 (32%)Ships in 1-3 Business DaysSubaru Outback Ring Set Piston

Part Number: 12033AC92A$83.50 MSRP: $121.02You Save: $37.52 (31%)Ships in 1-3 Business DaysSubaru Outback Ring Set Piston

Part Number: 12033AC91A$83.50 MSRP: $121.02You Save: $37.52 (31%)Ships in 1-3 Business DaysSubaru Outback Ring Set Piston

Part Number: 12033AC200$201.61 MSRP: $294.75You Save: $93.14 (32%)Ships in 1-3 Business DaysSubaru Outback Ring Set Piston

Part Number: 12033AC190$201.61 MSRP: $294.75You Save: $93.14 (32%)Ships in 1-3 Business DaysSubaru Outback Ring Set-Piston

Part Number: 12033AD47A$66.61 MSRP: $96.53You Save: $29.92 (31%)Ships in 1-3 Business DaysSubaru Outback Ring Set-Piston

Part Number: 12033AD49A$82.06 MSRP: $118.93You Save: $36.87 (31%)Ships in 1-3 Business DaysSubaru Outback Ring Set-Piston

Part Number: 12033AD48A$82.06 MSRP: $118.93You Save: $36.87 (31%)Ships in 1-3 Business DaysSubaru Outback PB000811 Ring Set

Part Number: 12033AB010$183.81 MSRP: $268.73You Save: $84.92 (32%)Ships in 1-2 Business DaysSubaru Outback Piston Ring Set

Part Number: 12033AB270$197.30 MSRP: $288.45You Save: $91.15 (32%)Ships in 1-3 Business Days

| Page 1 of 3 |Next >

1-20 of 51 Results

Subaru Outback Piston Ring Set

Our website stands as the go-to online destination for OEM Subaru Outback Piston Ring Set. With complete lines of genuine Subaru Outback Piston Ring Set available at unbeatable market prices, we ensure top quality, reliability, and durability. Each part comes backed by the manufacturer's warranty, reinforcing your trust in our offerings.

Subaru Outback Piston Ring Set Parts Questions & Experts Answers

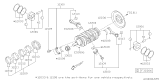

- Q: How to Prepare a Piston Ring Set for Side Clearance Check, End Gap Measurement, and Engine Assembly on a Subaru Outback?A:When preparing the Pistons and new ring sets, make sure they are matched in order to allow checking of their side clearance, end gap measurement and engine assembly. Before putting the rings on it, ensure that the piston ring side clearance is right by inserting some new rings into each groove and employing a feeler gauge to test the spaces between them at various points around every groove. Distinct clearances exist for different rings; compression rings ordinarily have a clearance of about 0.0015 to 0.004 inches. Then, confirm that the ring end gaps fall within specifications by slightly dragging feeler gauges through the ring ends. The standard ring gap (compression ring) is 0.010" - 0.020". Smaller gaps can be adjusted by careful filing of ring ends. Avoid extremely large gaps over 0.040". Subsequently, mount the rings correctly on each piston starting with oil control ring as it has three parts namely spacer/expander, upper side rail and lower side rail which must be carefully inserted into their respective grooves without using a piston ring installation tool.Then make sure that both upper and lower rails can rotate smoothly.Putting number two(middle)ring in place there should be an identification mark pointing up while number one(top)ring should also face upwards with its mark repeating these steps for remaining pistons ensuring accurate installation for each.

Related Subaru Outback Parts

Browse by Year

2025 Piston Ring Set 2024 Piston Ring Set 2023 Piston Ring Set 2022 Piston Ring Set 2021 Piston Ring Set 2020 Piston Ring Set 2019 Piston Ring Set 2018 Piston Ring Set 2017 Piston Ring Set 2016 Piston Ring Set 2015 Piston Ring Set 2014 Piston Ring Set 2013 Piston Ring Set 2012 Piston Ring Set 2011 Piston Ring Set 2010 Piston Ring Set 2009 Piston Ring Set 2008 Piston Ring Set 2007 Piston Ring Set 2006 Piston Ring Set 2005 Piston Ring Set 2004 Piston Ring Set 2003 Piston Ring Set 2002 Piston Ring Set 2001 Piston Ring Set 2000 Piston Ring Set 1999 Piston Ring Set 1998 Piston Ring Set 1997 Piston Ring Set 1996 Piston Ring Set