×

- Hello

- Login or Register

- Quick Links

- Live Chat

- Track Order

- Parts Availability

- RMA

- Help Center

- Contact Us

- Shop for

- Subaru Parts

- Subaru Accessories

My Garage

My Account

Cart

Genuine Subaru Legacy Drive Belt

Serpentine Belt- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

21 Drive Belts found

Subaru Legacy V Belt

Part Number: 23780AA010$38.81 MSRP: $56.25You Save: $17.44 (31%)Ships in 1-3 Business Days

Subaru Legacy A/C Belt

Part Number: 73323AC000$15.26 MSRP: $22.12You Save: $6.86 (32%)Ships in 1-3 Business Days

Subaru Legacy V Belt-18X5X874

Part Number: 809218370$14.46 MSRP: $20.95You Save: $6.49 (31%)Ships in 1-3 Business Days

Subaru Legacy V Belt 21X4X1628

Part Number: 809221130$43.13 MSRP: $62.50You Save: $19.37 (31%)Ships in 1-2 Business Days

Subaru Legacy V Belt 14X5X845

Part Number: 809214500$20.67 MSRP: $29.95You Save: $9.28 (31%)Ships in 1-3 Business Days

Subaru Legacy V Belt 21X4X2196

Part Number: 809221190$36.18 MSRP: $52.43You Save: $16.25 (31%)Ships in 1-2 Business Days

Subaru Legacy V Belt-21X4X1654

Part Number: 809221140$27.57 MSRP: $39.95You Save: $12.38 (31%)Ships in 1-2 Business Days

Subaru Legacy V Belt 21X4X1081

Part Number: 809221150$27.57 MSRP: $39.95You Save: $12.38 (31%)Ships in 1-3 Business Days

Subaru Legacy V Belt

Part Number: 809221080$33.71 MSRP: $48.85You Save: $15.14 (31%)Ships in 1-2 Business Days

Subaru Legacy A/C Belt

Part Number: 73323AC010$15.26 MSRP: $22.12You Save: $6.86 (32%)Ships in 1-3 Business Days

Subaru Legacy V Belt-18X6X887

Part Number: 809218260$14.12 MSRP: $19.95You Save: $5.83 (30%)Ships in 1-2 Business Days

Subaru Legacy A/C Belt

Part Number: 73013AA000$12.00 MSRP: $16.95You Save: $4.95 (30%)Ships in 1-3 Business Days

Subaru Legacy V-Belt

Part Number: 73323AE00A$15.26 MSRP: $22.12You Save: $6.86 (32%)Ships in 1-3 Business Days

Subaru Legacy V-Belt 18X6X891

Part Number: 809218200$14.12 MSRP: $19.95You Save: $5.83 (30%)Ships in 1-3 Business Days

Subaru Legacy V Belt 18X5X874

Part Number: 809218400$14.46 MSRP: $20.95You Save: $6.49 (31%)Ships in 1-3 Business Days

Subaru Legacy V Belt 18X5X874

Part Number: 809218340$14.46 MSRP: $20.95You Save: $6.49 (31%)Ships in 1-3 Business Days

Subaru Legacy V Belt

Part Number: 809221050$27.57 MSRP: $39.95You Save: $12.38 (31%)Ships in 1 Business DaySubaru Legacy V Belt

Part Number: 23780AA21A$36.23 MSRP: $52.50You Save: $16.27 (31%)Ships in 1-2 Business DaysSubaru Legacy A/C Belt

Part Number: 73323FA000$12.00 MSRP: $16.95You Save: $4.95 (30%)Ships in 1-3 Business Days

| Page 1 of 2 |Next >

1-20 of 21 Results

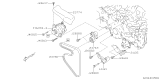

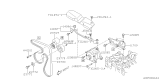

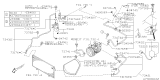

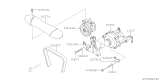

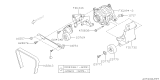

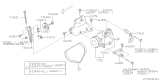

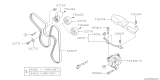

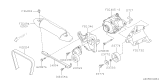

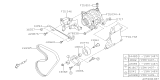

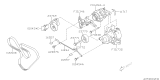

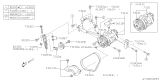

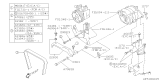

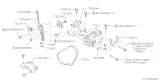

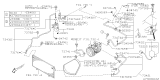

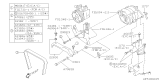

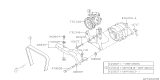

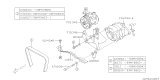

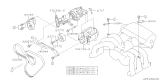

Subaru Legacy Drive Belt

Drive Belt in Subaru Legacy vehicles ensure essential connection of engine power to essential part including the alternator and A/C compressor. Demands on the drive system in Legacy require a serpentine belt to encircle all the components as it attaches to the crankshaft pulley. Drive Belt typically survive 100,000 miles of operation however they might need an early replacement due to indications of wear such as fraying or cracking. Several Legacy models applied V-belts and multi-groove belts in their drive systems as they helped increase belt traction efficiency while preventing slippage occurrences. TimeInterval belts equipped with toothed designs operate in precise applications because of their specific teeth configuration. New developments in Subaru Drive Belt design lead to dependable power transmission which supports vehicle operation at its optimum level.

Our website stands as the go-to online destination for OEM Subaru Legacy Drive Belt. With complete lines of genuine Subaru Legacy Drive Belt available at unbeatable market prices, we ensure top quality, reliability, and durability. Each part comes backed by the manufacturer's warranty, reinforcing your trust in our offerings.

Subaru Legacy Drive Belt Parts Questions & Experts Answers

- Q: What is the Role of the Drive Belt Located at the Front of the Engine on a Subaru Legacy?A:Drivebelts on the engine's front side are important in running the car and other parts. Their nature of work and material used in making them make them to wear out with time leading to need for routine check-ups and adjustments to prevent major engine damage. The number of belts depends on what accessories are installed: some drivebelts operate alternators, air conditioners and power steering pumps as well. You can visually inspect the belts by opening the hood while the engine is off since they are positioned right at its very front. Feel it using your fingers to see if there are any cracks, splitting apart, fraying or glazing. In addition, all ribs should be equal in depth from one another when viewed from below. Belt deflection can be checked by applying pressure half-way between pulleys for each belt. There are two adjusting assemblies mounted on the front of the engine that can perform this task if required: a tension adjustment assembly or a pivot assembly; each belt will have one adjusting assembly with a slider bolt and a lock bolt. The slider bolt is turned to adjust drivebelt tension after loosening the lock bolt. Do not attempt moving this assembly using a prybar during belt adjustment process. When replacing the belt, remove it by slipping off the pulleys; ideally, all belts should be changed at once. In order that you fit in properly replacement belts must be marked together with corresponding pulley grooves having similar details about dimensions; take along old ones when going for new ones so as to compare directly lengthwise , widthwise , design-wise . Lastly tighten all belts carefully .

Related Subaru Legacy Parts

Browse by Year

2025 Drive Belt 2024 Drive Belt 2023 Drive Belt 2022 Drive Belt 2021 Drive Belt 2020 Drive Belt 2019 Drive Belt 2018 Drive Belt 2017 Drive Belt 2016 Drive Belt 2015 Drive Belt 2014 Drive Belt 2013 Drive Belt 2012 Drive Belt 2011 Drive Belt 2010 Drive Belt 2009 Drive Belt 2008 Drive Belt 2007 Drive Belt 2006 Drive Belt 2005 Drive Belt 2004 Drive Belt 2003 Drive Belt 2002 Drive Belt 2001 Drive Belt 2000 Drive Belt 1999 Drive Belt 1998 Drive Belt 1997 Drive Belt 1996 Drive Belt 1995 Drive Belt 1994 Drive Belt 1993 Drive Belt 1992 Drive Belt 1991 Drive Belt 1990 Drive Belt