×

- Hello

- Login or Register

- Quick Links

- Live Chat

- Track Order

- Parts Availability

- RMA

- Help Center

- Contact Us

- Shop for

- Subaru Parts

- Subaru Accessories

My Garage

My Account

Cart

Genuine Subaru Legacy Piston

Engine Pistons- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

51 Pistons found

Subaru Legacy Piston Set RH

Part Number: 12013AB250$79.27 MSRP: $114.88You Save: $35.61 (31%)Ships in 1-3 Business Days

Subaru Legacy Piston Set RH OS0.25

Part Number: 12013AB550$65.35 MSRP: $94.72You Save: $29.37 (32%)Ships in 1-3 Business Days

Subaru Legacy Piston Set RH

Part Number: 12013AB260$79.27 MSRP: $114.88You Save: $35.61 (31%)Ships in 1-3 Business Days

Subaru Legacy Piston Set RH

Part Number: 12013AB270$79.27 MSRP: $114.88You Save: $35.61 (31%)Ships in 1-3 Business DaysSubaru Legacy Piston Set Os 0.25

Part Number: 12006AE490$82.95 MSRP: $120.22You Save: $37.27 (31%)Ships in 1-3 Business DaysSubaru Legacy PISTON SET STD A

Part Number: 12006AE590$87.22 MSRP: $126.40You Save: $39.18 (31%)Ships in 1-3 Business DaysSubaru Legacy Piston Set Os 0.25

Part Number: 12006AE530$82.95 MSRP: $120.22You Save: $37.27 (31%)Ships in 1-3 Business DaysSubaru Legacy Piston Set Std B

Part Number: 12006AE520$82.95 MSRP: $120.22You Save: $37.27 (31%)Ships in 1-3 Business DaysSubaru Legacy Piston Set Std A

Part Number: 12006AE510$82.95 MSRP: $120.22You Save: $37.27 (31%)Ships in 1-3 Business DaysSubaru Legacy PISTON SET OS 0.25

Part Number: 12006AE610$87.07 MSRP: $126.18You Save: $39.11 (31%)Ships in 1-3 Business DaysSubaru Legacy Piston Set Std A

Part Number: 12006AE470$82.95 MSRP: $120.22You Save: $37.27 (31%)Ships in 1-3 Business DaysSubaru Legacy Piston Set Os 0.50

Part Number: 12006AE540$82.95 MSRP: $120.22You Save: $37.27 (31%)Ships in 1-3 Business DaysSubaru Legacy Piston Set Os 0.50

Part Number: 12006AE500$82.95 MSRP: $120.22You Save: $37.27 (31%)Ships in 1-2 Business DaysSubaru Legacy Piston Set Std B

Part Number: 12006AE480$82.95 MSRP: $120.22You Save: $37.27 (31%)Ships in 1-3 Business DaysSubaru Legacy PISTON SET OS 0.50

Part Number: 12006AE620$87.07 MSRP: $126.18You Save: $39.11 (31%)Ships in 1-3 Business DaysSubaru Legacy PISTON SET STD B

Part Number: 12006AE600$87.22 MSRP: $126.40You Save: $39.18 (31%)Ships in 1-3 Business DaysSubaru Legacy Piston Set RH Std A

Part Number: 12013AB450$72.14 MSRP: $104.55You Save: $32.41 (31%)Ships in 1-3 Business DaysSubaru Legacy Piston Set RH Std B

Part Number: 12013AB540$65.35 MSRP: $94.72You Save: $29.37 (32%)Ships in 1-3 Business DaysSubaru Legacy Piston Set RH OS0.50

Part Number: 12013AB560$65.35 MSRP: $94.72You Save: $29.37 (32%)Ships in 1-3 Business DaysSubaru Legacy Piston Set RH OS0.50

Part Number: 12013AB480$72.14 MSRP: $104.55You Save: $32.41 (31%)Ships in 1-3 Business Days

| Page 1 of 3 |Next >

1-20 of 51 Results

Subaru Legacy Piston

Our website stands as the go-to online destination for OEM Subaru Legacy Piston. With complete lines of genuine Subaru Legacy Piston available at unbeatable market prices, we ensure top quality, reliability, and durability. Each part comes backed by the manufacturer's warranty, reinforcing your trust in our offerings.

Subaru Legacy Piston Parts Questions & Experts Answers

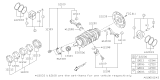

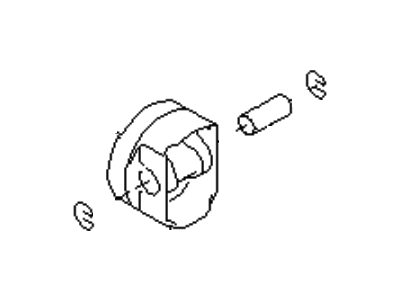

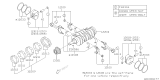

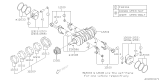

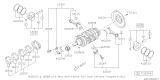

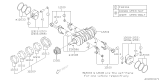

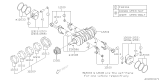

- Q: How to remove pistons and piston pins on Subaru Legacy?A:Temporarily install the Crankshaft pulley bolt in the crankshaft front end to enable turning of the crankshaft and check for a wear ridge at the top of each cylinder; if present, it must be machined out before removing the pistons, using a ridge reamer to eliminate the raised material. Remove the plugs from the four service holes with an Allen wrench to access the piston pin cir clips, soaking them with penetrating oil if they are difficult to remove, and ensuring the wrench is fully inserted to avoid rounding off the hexagonal opening. Position the piston at bottom dead center by turning the crankshaft, then use needle-nose pliers through the service holes to remove the cir clips, utilizing a small flashlight to ensure proper alignment. For piston pin removal, a special tool is required to extract the pins through the service hole, which can be fabricated from steel rod; if the pins are varnished, a slide hammer or striking the tool may be necessary. Keep the pistons and pins together, marking the pistons for reinstallation in their original locations. The pistons can remain in the cylinder bores until the crankcase is separated, at which point they can be driven out with a wooden or plastic hammer handle, or they can be removed beforehand by turning the crankshaft slowly until the connecting rods push the pistons out slightly, inserting cleaned and oiled piston pins into the connecting rods through the service holes, and then turning the crankshaft until the pin pushes the piston from the bore before pulling the pistons out.