×

- Hello

- Login or Register

- Quick Links

- Live Chat

- Track Order

- Parts Availability

- RMA

- Help Center

- Contact Us

- Shop for

- Subaru Parts

- Subaru Accessories

My Garage

My Account

Cart

Genuine Subaru Outback Piston

Engine Pistons- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

40 Pistons found

Subaru Outback Piston Set RH

Part Number: 12013AB250$79.27 MSRP: $114.88You Save: $35.61 (31%)Ships in 1-3 Business Days

Subaru Outback Piston Set RH OS0.25

Part Number: 12013AB550$65.35 MSRP: $94.72You Save: $29.37 (32%)Ships in 1-3 Business Days

Subaru Outback Piston Set RH

Part Number: 12013AB260$79.27 MSRP: $114.88You Save: $35.61 (31%)Ships in 1-3 Business Days

Subaru Outback Piston Set RH

Part Number: 12013AB270$79.27 MSRP: $114.88You Save: $35.61 (31%)Ships in 1-3 Business DaysSubaru Outback Piston Set Os 0.25

Part Number: 12006AE490$82.95 MSRP: $120.22You Save: $37.27 (31%)Ships in 1-3 Business DaysSubaru Outback PISTON SET STD A

Part Number: 12006AE590$87.22 MSRP: $126.40You Save: $39.18 (31%)Ships in 1-3 Business DaysSubaru Outback Piston Set Os 0.25

Part Number: 12006AE530$82.95 MSRP: $120.22You Save: $37.27 (31%)Ships in 1-3 Business DaysSubaru Outback Piston Set Std B

Part Number: 12006AE520$82.95 MSRP: $120.22You Save: $37.27 (31%)Ships in 1-3 Business DaysSubaru Outback Piston Set Std A

Part Number: 12006AE510$82.95 MSRP: $120.22You Save: $37.27 (31%)Ships in 1-3 Business DaysSubaru Outback PISTON SET OS 0.25

Part Number: 12006AE610$87.07 MSRP: $126.18You Save: $39.11 (31%)Ships in 1-3 Business DaysSubaru Outback Piston Set Std A

Part Number: 12006AE470$82.95 MSRP: $120.22You Save: $37.27 (31%)Ships in 1-3 Business DaysSubaru Outback Piston Set Os 0.50

Part Number: 12006AE540$82.95 MSRP: $120.22You Save: $37.27 (31%)Ships in 1-3 Business DaysSubaru Outback Piston Set Os 0.50

Part Number: 12006AE500$82.95 MSRP: $120.22You Save: $37.27 (31%)Ships in 1-2 Business DaysSubaru Outback Piston Set Std B

Part Number: 12006AE480$82.95 MSRP: $120.22You Save: $37.27 (31%)Ships in 1-3 Business DaysSubaru Outback PISTON SET OS 0.50

Part Number: 12006AE620$87.07 MSRP: $126.18You Save: $39.11 (31%)Ships in 1-3 Business DaysSubaru Outback PISTON SET STD B

Part Number: 12006AE600$87.22 MSRP: $126.40You Save: $39.18 (31%)Ships in 1-3 Business DaysSubaru Outback Piston Set RH Std A

Part Number: 12013AB450$72.14 MSRP: $104.55You Save: $32.41 (31%)Ships in 1-3 Business DaysSubaru Outback Piston Set RH Std B

Part Number: 12013AB540$65.35 MSRP: $94.72You Save: $29.37 (32%)Ships in 1-3 Business DaysSubaru Outback Piston Set RH OS0.50

Part Number: 12013AB560$65.35 MSRP: $94.72You Save: $29.37 (32%)Ships in 1-3 Business DaysSubaru Outback Piston Set RH OS0.50

Part Number: 12013AB480$72.14 MSRP: $104.55You Save: $32.41 (31%)Ships in 1-3 Business Days

| Page 1 of 2 |Next >

1-20 of 40 Results

Subaru Outback Piston

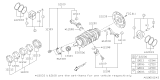

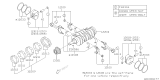

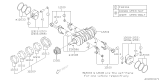

The internal combustion engine of Subaru Outback vehicles operates through its Piston which converts combustion energy into vehicle-driving power. The crankshaft receives powered motion from expanding gases through the Piston as part of its operational method for engine efficiency. The aluminum alloy material makes up the Pistons in Subaru Outback engines because it provides both strength and lightweight features although high-performance models might use forged or billet Piston structures. Different types of Pistons have been applied in Outback models throughout the years yet trunk replacement units remain consistent by providing side force support while the lubricating system includes oil rings. Engine applications relying on high speeds so prefer slipper replacement parts since these components reduce weight to deliver better system balance and operational efficiency. Engine performance and longevity depend strongly on the design specifications and material choice because these factors demonstrate the sophisticated engineering work Subaru performs in their engine formulation.

Our website stands as the go-to online destination for OEM Subaru Outback Piston. With complete lines of genuine Subaru Outback Piston available at unbeatable market prices, we ensure top quality, reliability, and durability. Each part comes backed by the manufacturer's warranty, reinforcing your trust in our offerings.

Subaru Outback Piston Parts Questions & Experts Answers

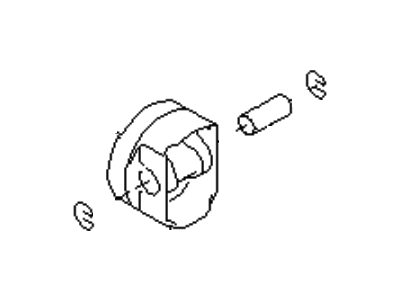

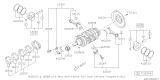

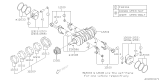

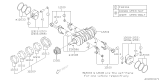

- Q: How to install pistons and piston pins on Subaru Outback?A:Position the piston ring end gaps at the correct intervals around the piston. Install new piston pin circlips in the inner piston pin bore groove of each piston, ensuring the correct positioning and installation in the groove opposite the crankcase service hole. Lubricate the skirt and rings with clean engine oil, then use a piston ring compressor on the number one piston, leaving the skirt protruding about 1 inch to guide the piston into the cylinder. Compress the rings as far as possible. Rotate the Crankshaft until the number one and two connecting rods are at bottom dead center, aligning them with the center of the cylinder. Gently guide the number one piston into the cylinder, making sure the mark on the piston crown faces the front of the engine. Tap the exposed edge of the ring compressor to ensure contact with the crankcase. Carefully tap on the top of the piston with a wood or plastic hammer handle to push it into the cylinder, maintaining pressure on the ring compressor. If any resistance is felt, stop immediately and address the issue. Push the piston in until the piston pin bore and the small end of the connecting rod align in the service hole. Lubricate the piston pin with clean engine oil and insert it into the piston and connecting rod. Install the outer circlip in the piston pin bore groove. Repeat the procedure for the number two piston, applying RTV sealant to the service hole plug gaskets and tightening the plugs. Rotate the crankshaft until the number three and four connecting rods are at bottom dead center, aligning them with the center of the cylinder. Repeat the piston and pin installation procedure for pistons three and four. Apply RTV sealant to the service hole plug and cover gaskets, then install the plug and cover, tightening the screws.