×

- Hello

- Login or Register

- Quick Links

- Live Chat

- Track Order

- Parts Availability

- RMA

- Help Center

- Contact Us

- Shop for

- Subaru Parts

- Subaru Accessories

My Garage

My Account

Cart

Genuine Subaru Impreza Piston

Engine Pistons- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

33 Pistons found

Subaru Impreza Piston Set RH

Part Number: 12013AB250$79.27 MSRP: $114.88You Save: $35.61 (31%)Ships in 1-3 Business Days

Subaru Impreza Piston Set RH

Part Number: 12013AB260$79.27 MSRP: $114.88You Save: $35.61 (31%)Ships in 1-3 Business Days

Subaru Impreza Piston Set RH

Part Number: 12013AB270$79.27 MSRP: $114.88You Save: $35.61 (31%)Ships in 1-3 Business DaysSubaru Impreza Piston Set RH

Part Number: 12013AC080$67.48 MSRP: $97.80You Save: $30.32 (31%)Ships in 1-3 Business DaysSubaru Impreza Piston Set RH

Part Number: 12013AC070$67.48 MSRP: $97.80You Save: $30.32 (31%)Ships in 1-3 Business DaysSubaru Impreza Piston Set RH

Part Number: 12013AC060$67.48 MSRP: $97.80You Save: $30.32 (31%)Ships in 1-3 Business DaysSubaru Impreza PISTON SET-RH OS0.50

Part Number: 12013AC520$70.90 MSRP: $102.75You Save: $31.85 (31%)Ships in 1-2 Business DaysSubaru Impreza PISTON SET-RH OS0.25

Part Number: 12013AC510$70.90 MSRP: $102.75You Save: $31.85 (31%)Ships in 1-2 Business DaysSubaru Impreza PISTON SET-RH STD B

Part Number: 12013AC500$70.90 MSRP: $102.75You Save: $31.85 (31%)Ships in 1-2 Business DaysSubaru Impreza PISTON SET-RH STD A

Part Number: 12013AC490$70.90 MSRP: $102.75You Save: $31.85 (31%)Ships in 1-2 Business DaysSubaru Impreza PISTON SET OS 0.50

Part Number: 12006AE660$87.07 MSRP: $126.18You Save: $39.11 (31%)Ships in 1-2 Business DaysSubaru Impreza PISTON SET OS 0.25

Part Number: 12006AE650$87.07 MSRP: $126.18You Save: $39.11 (31%)Ships in 1-2 Business DaysSubaru Impreza PISTON SET STD A

Part Number: 12006AE630$87.07 MSRP: $126.18You Save: $39.11 (31%)Ships in 1-2 Business DaysSubaru Impreza PISTON SET STD B

Part Number: 12006AE640$87.07 MSRP: $126.18You Save: $39.11 (31%)Ships in 1-2 Business DaysSubaru Impreza Piston Set RH

Part Number: 12013AB490$65.60 MSRP: $95.07You Save: $29.47 (31%)Ships in 1-3 Business DaysSubaru Impreza Piston Set RH

Part Number: 12013AB500$65.60 MSRP: $95.07You Save: $29.47 (31%)Ships in 1-3 Business DaysSubaru Impreza Piston Set RH

Part Number: 12013AB510$65.60 MSRP: $95.07You Save: $29.47 (31%)Ships in 1-2 Business DaysSubaru Impreza Piston Set RH Std A

Part Number: 12013AB690$65.49 MSRP: $94.92You Save: $29.43 (32%)Ships in 1-3 Business DaysSubaru Impreza Piston Set RH OS0.50

Part Number: 12013AB720$65.49 MSRP: $94.92You Save: $29.43 (32%)Ships in 1-3 Business DaysSubaru Impreza Piston Set RH OS0.25

Part Number: 12013AB710$65.49 MSRP: $94.92You Save: $29.43 (32%)Ships in 1-3 Business Days

| Page 1 of 2 |Next >

1-20 of 33 Results

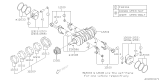

Subaru Impreza Piston

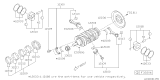

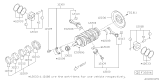

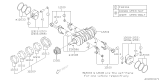

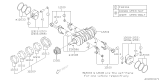

The Piston in Subaru Impreza vehicles is an essential part of the engine based on internal combustion where combustion fuel is converted into power required for vehicle motion. It works by exerting pressure on the crankshaft from expanding gaseous fuel for effective engine performance. Commonly made of aluminum alloys for durability and weight-reducibility, Subaru might also use forged or billet Piston on racing cars. Various types of Piston are applied in models of the Impreza over the years, such as trunk Piston that come with side forces and are lubricated via oil rings. For high speed performance, slipper Piston are preferred because of their light weight design which is in contrast with two stroke engines where deflector Piston are applied to maximize even the gas flow. The precise engineering of such replacement parts improves its performance as well as makes the automobile durable to cover the variable needs of Subaru Impreza car.

Our website stands as the go-to online destination for OEM Subaru Impreza Piston. With complete lines of genuine Subaru Impreza Piston available at unbeatable market prices, we ensure top quality, reliability, and durability. Each part comes backed by the manufacturer's warranty, reinforcing your trust in our offerings.

Subaru Impreza Piston Parts Questions & Experts Answers

- Q: How to prepare and remove pistons and piston pins on Subaru Impreza?A:The Crankshaft pulley bolt is temporarily installed at the front end of the crankshaft to allow for turning. If there is a wear ridge at the top of each cylinder, machine it out. The four service holes plugs are removed out using an Allen wrench so as to access piston pin circlips. In case the removing process becomes difficult for these plugs, soak them with penetrating oil and make sure that the tool completely fits into round off opening. By turning the crankshaft, place the piston at bottom dead center and remove its circlip with needle-nose pliers through these service holes. Through this service hole use either a special removal tool or a homemade one to pull out piston pins from inside them. Keep pistons and pins together; mark them for reinstallation purposes. Pistons can be left in the cylinder bores until separation of the crankcase or driven out by means of a wooden or plastic hammer handle; conversely, before separating the crankcase, pistons can be taken-out by slowly turning over onerous shaft till connecting rods push them just beyond their very slight movement limits thus inserting piston pins into such rods and then turn back cranks thus pushing pistons away from bores prior to pulling them outright.