×

- Hello

- Login or Register

- Quick Links

- Live Chat

- Track Order

- Parts Availability

- RMA

- Help Center

- Contact Us

- Shop for

- Subaru Parts

- Subaru Accessories

My Garage

My Account

Cart

Genuine Subaru Outback Turbocharger

Turbo- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

9 Turbochargers found

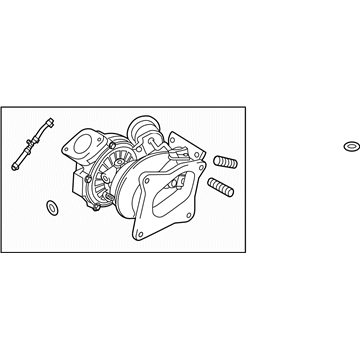

Subaru Outback TURBOCHARGER Assembly

Part Number: 14411AA532$897.61 MSRP: $1320.82You Save: $423.21 (33%)Ships in 1-3 Business DaysSubaru Outback CHGR ASSY-TURBO

Part Number: 14411AA963$960.50 MSRP: $1416.67You Save: $456.17 (33%)Ships in 1-3 Business DaysSubaru Outback TURBOCHARGER Assembly

Part Number: 14411AA51A$1446.41 MSRP: $2133.35You Save: $686.94 (33%)Ships in 1-2 Business DaysSubaru Outback TURBOCHARGER Assembly

Part Number: 14411AA760$1417.47 MSRP: $2090.67You Save: $673.20 (33%)Ships in 1-3 Business DaysSubaru Outback TURBOCHARGER Assembly

Part Number: 14411AA51B$1446.41 MSRP: $2133.35You Save: $686.94 (33%)Ships in 1-3 Business DaysSubaru Outback TURBOCHARGER Assembly

Part Number: 14411AA670$1621.15 MSRP: $2391.08You Save: $769.93 (33%)Ships in 1-3 Business DaysSubaru Outback TURBOCHARGER Assembly

Part Number: 14411AA531$897.61 MSRP: $1320.82You Save: $423.21 (33%)Ships in 1-3 Business DaysSubaru Outback TURBOCHARGER Assembly

Part Number: 14411AA510$1446.41 MSRP: $2133.35You Save: $686.94 (33%)Ships in 1-3 Business Days

Subaru Outback Turbocharger

Our website stands as the go-to online destination for OEM Subaru Outback Turbocharger. With complete lines of genuine Subaru Outback Turbocharger available at unbeatable market prices, we ensure top quality, reliability, and durability. Each part comes backed by the manufacturer's warranty, reinforcing your trust in our offerings.

Subaru Outback Turbocharger Parts Questions & Experts Answers

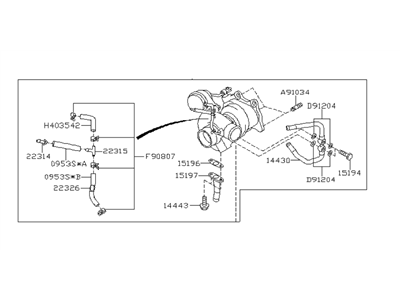

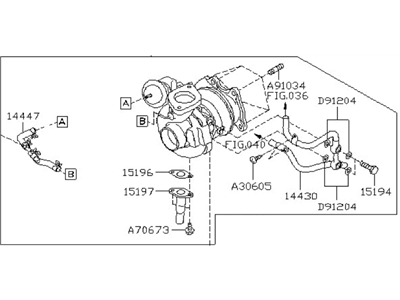

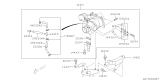

- Q: How to inspect the Turbocharger on Subaru Outback?A:A turbocharger system increases engine horse power by means of an exhaust gas-driven turbine that turns an impeller, or compressor, which in turn pressurizes the air entering the intake manifold. The turbocharger assembly is composed of two separate castings, the housing for the turbine is cast iron and the housing for the compressor is aluminum. The waste gate valve is designed to restrict the maximum boost level by allowing some of the exhaust gases to bypass the turbine when boost pressure gets too high. The wastegate controller solenoid valve keeps the wastegate controller closed to optimize the pressure on the outlet side of the compressor. The air bypass valve reduces the braking effect on the turbocharger by routing the excess air back to the turbocharger inlet duct. The turbocharger is lubricated by engine oil pumped through the turbocharger housing by the engine oil pump. You can inspect some things yourself such as a cracked turbo mounting flange, a blocked or restricted oil supply line, a worn out or overheated turbine/compressor shaft bearing or a defective waste gate actuator.